Orca Semiconductor enables Industry 4.0 applications

Orca Semiconductor has introduced the OS2000 IO-Link communications transceiver, designed to improve the intelligence for Industry 4.0 in industrial applications.

The OS2000 enables seamless, bi-directional communication between sensors, actuators, and control systems, boosting productivity, improving efficiency and reducing downtime throughout the factory floor.

Orca Semi will demonstrate the OS2000 at the SPS conference, November 12-14, 2024, in Hall 8, stand 210.8.

This announcement follows the launch of the OS1000, Orca Semi's power management integrated circuit (PMIC) product for wearables, in June.

Since early 2023, Orca Semi has defined the initial products with alpha customers, built a team of highly experienced engineers in Milan, Italy and executed three product tape-outs to date, accelerating to a first design win and POs for revenue ramp in late 2024 with a tier 1 wearable OEM.

"We are continuing our aggressive design and delivery of customized, application specific analog products to fill the void neglected by Big Analog," said Andrew Baker, CEO of Orca Semiconductor. "IO-Link transceivers are the backbone of Industry 4.0, driving intelligence on the factory floor by enabling seamless communication between devices. With increased factory data, manufacturers can boost productivity, reduce downtime, and optimize efficiency, significantly lowering operating costs and creating a more agile, intelligent manufacturing process. The OS2000 is Orca Semi's first Smart Factory platform product to enable our more ambitious plans for more highly integrated innovative solutions in the near future."

Orca's OS2000 is an IO-Link communication transceiver that can be used in either IO-Link master or device applications and features two control interface options: I2C or GPIO (general input output). The I2C mode allows control over advanced features and diagnostics not available in GPIO mode.

OS2000 integrates many features that simplify designs, including two linear voltage regulators, one digital input channel, an internal clock generator, and integrated surge protection for input power, CQ, and the digital input channel. The linear 5V voltage regulators may be bypassed if an external 5V source is available. The internal clock generator may be used to provide an IO-Link timing-compliant clock to the system microcontroller, simplifying designs. It features five different output frequency options allowing it to work with most microcontrollers. OS2000 is designed to be footprint and function compatible with the MAX22515 from Analog Devices providing an easy direct replacement in any application.

Key Features

Power Supply Input (VLP) from 8V to 36V

Control options: I2C or GPIO. Some functions limited to I2C only

Auxiliary Digital Input (DI)

C/Q Driver

Driver Current settable to 50mA,

100mA, 200mA or 250mA

Driver Slew Rate (I2C Mode)

Optional oscillator output for microcontroller clock

IO-Link Wake-Up Detection and Wake-Up Generation

Internal 20mA, 3.3V and 5.0V Linear Regulators

Operates at COM1, COM2, and COM3 Rates

Extended Temperature Range Operation-40°C to +125°C

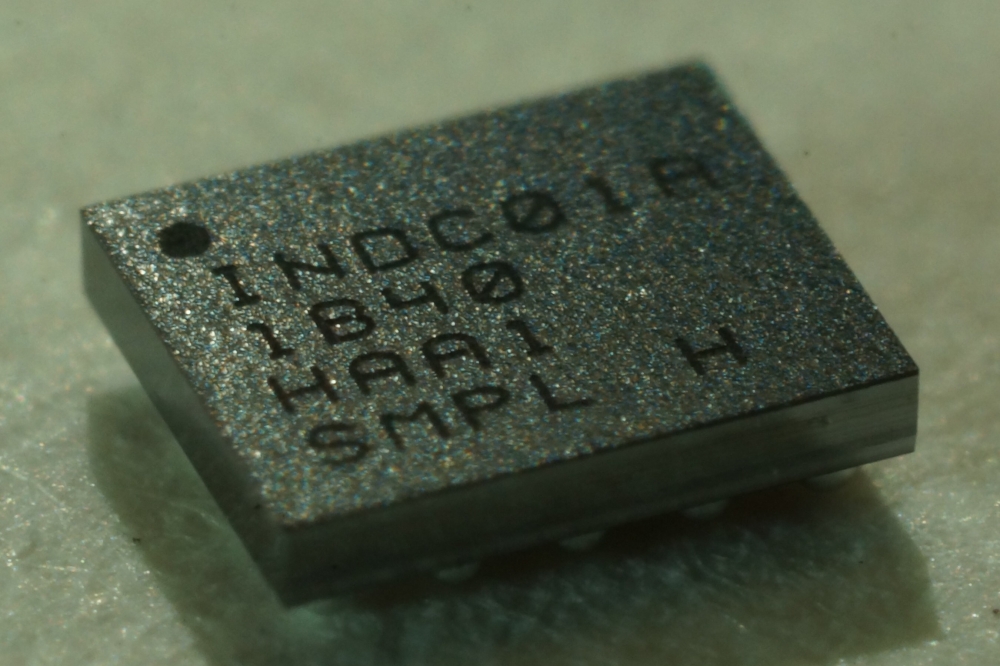

Packaging: WLCSP-20 (2.5mm x 2.0mm)

The OS2000 will be available for alpha customer engagement in December with general sampling in Q2 2025. Mass production of OS2000 is expected late 2025.