PlayNitride selects Veeco’s Lumina MOCVD system

PlayNitride, an industry leader in MicroLED technology, has qualified Veeco’s Lumina® MOCVD system for production of next-generation MicroLEDs, and also placed an order for two systems for delivery in 2025.

PlayNitride’s decision followed a successful evaluation of Veeco’s Lumina® MOCVD system.

“We’re pleased to partner with Veeco for production and commercialization of our industry-leading MicroLED technology for wearables, TVs, transparent displays and automotive,” stated Dr. Charles Li, CEO & Chairman at PlayNitride. “The Lumina system is uniquely positioned to exceed market requirements by providing best-in-class performance and productivity advantages, each essential in advancing our technology and cost roadmap.”

“Qualification of our Lumina system by PlayNitride, a leading-edge provider of MicroLED technology, is an exciting win for our best-in-class MOCVD technology,” commented Anil Vijayendran, Vice President, MOCVD Product Line Management. “Veeco’s Lumina system is extensively used in high volume manufacturing utilizing the proven performance of our core TurboDisc® technology. Industry leaders such as PlayNitride require solutions enabling excellent uniformity, brightness, defectivity, and unmatched cost of ownership, all of which our Lumina system delivers.”

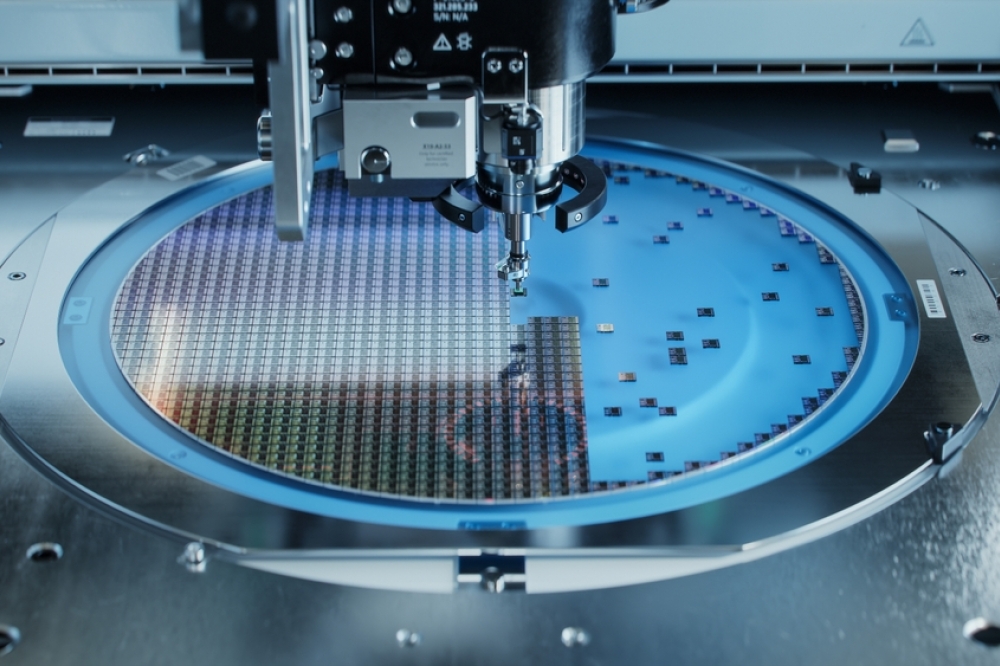

Core to the Lumina system is Veeco’s industry-leading MOCVD TurboDisc technology, featuring excellent thickness and compositional uniformity and low defectivity for exceptional yield. Veeco’s proprietary technology also supports high-throughput enabled by a clean reactor over long campaigns. Providing a seamless wafer size transition, the system is capable of depositing high quality arsenic phosphide (As/P) epitaxial layers on wafers up to eight inches in diameter. The Lumina system allows users to customize their systems for maximum value in delivering IR-LEDs, Edge-Emitting Lasers, VCSELs, and Solar Cells in high volume production.