Biometric ID drives semiconductor manufacturing security and efficiency

The wrist-worn Nymi Band using biometric ID is expediting secure, hands-free authentication across semiconductor fabs, dramatically increasing productivity.

By Arista Biometrics

Semiconductor manufacturers have traditionally been hindered by the need to authenticate operator identity across a complex patchwork of access points, workstations, and tools. Using badges, passwords, and other means of authentication has been slow, requiring the use of gloved hands, and could always be utilized independent of the intended operator, an inherent security flaw.

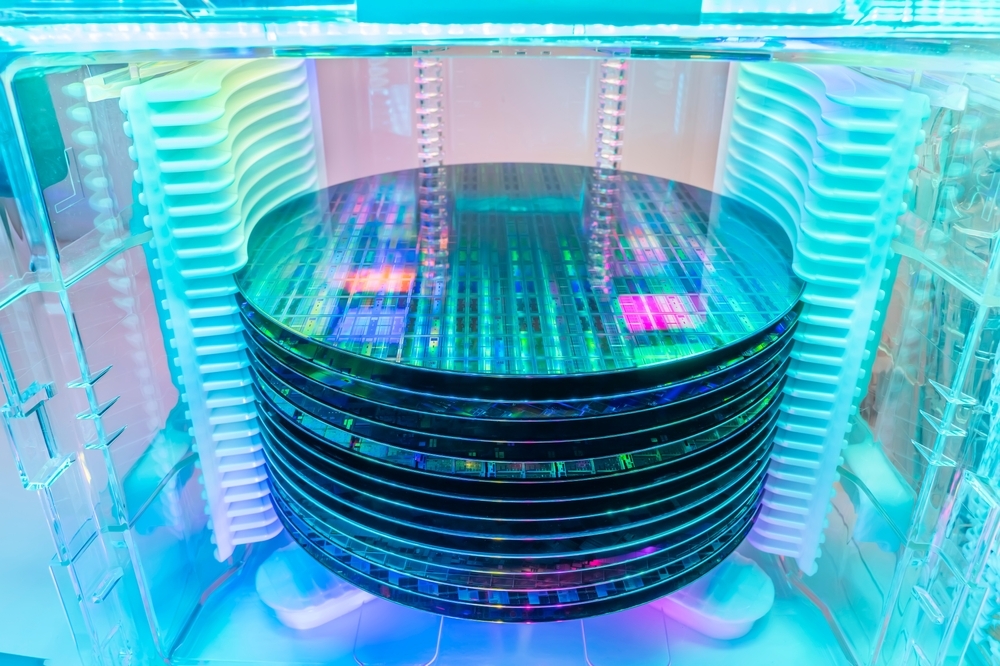

Wafer fabrication is a highly intricate process that demands precise execution, stringent control, and strong security protocols to safeguard intellectual property, protect sensitive information, and adhere to industry regulations. Conventional authentication approaches, such as passwords and hardware tokens, are often inadequate, inefficient, and insecure, particularly for deskless workers. This challenge is especially pronounced in semiconductor fabs, where employees are required to wear gloves and full-body suits while working in cleanroom conditions.

In response, semiconductor manufacturers are increasingly turning to wearable biometric ID products like wrist-worn Nymi Bands to securely speed authentication in a hands-free manner.

These innovative, wearable wristbands blend biometrics, security, and privacy, digitally empowering employees with passwordless, contactless workflow across applications, systems, and networks.

Employees simply wear their Nymi Band, authenticate as little as once per day, and work until they want to disconnect, according to the OEM’s solutions brief “Connected Workers in a Passwordless World.”

When used to facilitate employee entry to access points, tools, and equipment, wearable biometric identity products are significantly increasing security and productivity.

Mobile workstations are now available with an optional NFC reader that can be used throughout semiconductor manufacturing facilities with biometric wearables and other forms of identification.

Now, computing solutions providers are providing scanners that can instantly read biometric wearables such as bands. When used with equipment such as mobile workstations, the combination is enabling seamless identification and authentication of authorized users throughout semiconductor fabs, further enhancing safety and efficiency.

“Using unique biometric ID wearables like Nymi bands is not only more secure than utilizing credentials [such as passwords] that can be compromised, but also enables much faster access to a wide range of tools. When utilized with equipment such as mobile workstations or handheld devices that require authorization to use, the combination unlocks greater productivity,” says Paul Shu of ARISTA Corporation, a leading provider of computing platforms and visualization display products for semiconductor manufacturing environments.

“Ultimately, the wearable bands provide much greater security to semiconductor fabs. Employees cannot take someone else’s band and log into a computer since each band corresponds with the operator’s specific biometric data,” adds Shu.

Streamlining connectivity

Semiconductor fabs often consist of hundreds of systems and applications that require proper user identification to access and use. Traditionally, the burden of providing and managing separate identification credentials has fallen on the employee, which has resulted in increased stress and decreased productivity.

The wafer fabrication process in semiconductor manufacturing takes place in an ultraclean environment where high-precision equipment is used, necessitating strict trackability and traceability.

Deskless operators in these facilities move between multiple machines, systems, and terminals throughout their shifts. Depending on the task, they may use devices such as desktop computers, tablets, or human-machine interfaces (HMIs). This frequent movement, coupled with the need to switch between various systems, makes conventional authentication methods like password entry or USB keys inconvenient, prone to errors, and inefficient.

Additionally, the use of PPE garments designed to minimize contamination from the operator further complicates traditional authentication processes like typing passwords or using hardware tokens.

Today, a new approach is enabling identity to be authenticated once per person while allowing the platform to facilitate connections to the required systems. Employees no longer assume the burden of manually authenticating their identity at each access point.

An example of this more streamlined, integrated approach to identification and access is the increased adoption of the Nymi Band at semiconductor fabs. The biometric wristband works in conjunction with the Nymi Connected Worker Platform, which creates an intermediary layer between employees and their employer’s complicated IT infrastructure. The Platform establishes the biometric security and privacy of its users and allows them to inter-operate between disparate technologies.

Employees authenticate to their Nymi Band as little as once per day through their fingerprint, which takes less than a second. The device’s on-body detection capability enables an assigned employee to use it continually throughout all of their integrated applications. Employees simply take off their Nymi Band to deactivate and disconnect from their workplace, according to the OEM’s solutions brief.

To enhance security, the Nymi Band is authenticated via fingerprint and verified against a mathematical template created at enrollment. Biometric images are never stored, and templates are secured locally in the band.

Employees can use their wearable band to efficiently gain hands-free access to terminals, email, applications, doors, and elevators throughout a facility, as required for their official duties. Access can be custom set according to the user’s role, to appropriately protect sensitive information and areas.

Paul Shu of ARISTA Corporation notes that biometric wearables pair with short-range wireless Near Field Communication (NFC) technology to expedite identification, authorized access, and communication. This is the case, for example, with ARISTA’s mobile workstations, which are now available with an optional NFC reader that can be used throughout semiconductor fabs with biometric wearables and other forms of identification. NFC readers and related technologies are widely employed across industries for tasks such as asset management, inventory control, equipment monitoring, and enhancing security.

While other mobile workstations must be plugged into the wall to function, ARISTA’s Mobile Operator Workstation can move from place to place while in operation free of wires due to its powerful lithium-ion battery. Wi-Fi capability is built into the workstation to allow for uninterrupted wireless communication in all corners of the cleanroom and fab. In addition, most advanced semiconductor fabs today have Wi-Fi-based system backbones connected to legacy subsystems, meaning the workstation can communicate directly with the fab’s server.

“Biometric ID wearables like Nymi Bands are much more secure than any other NFC device, so are ideal for logging into a wide range of devices at semiconductor fabs. When used with equipment such as mobile workstations, the combination can further promote productivity, allowing the work to occur where needed. The technology provides greater security, convenience, and efficiency, so we expect its use to grow in the industry and beyond,” concludes Shu.