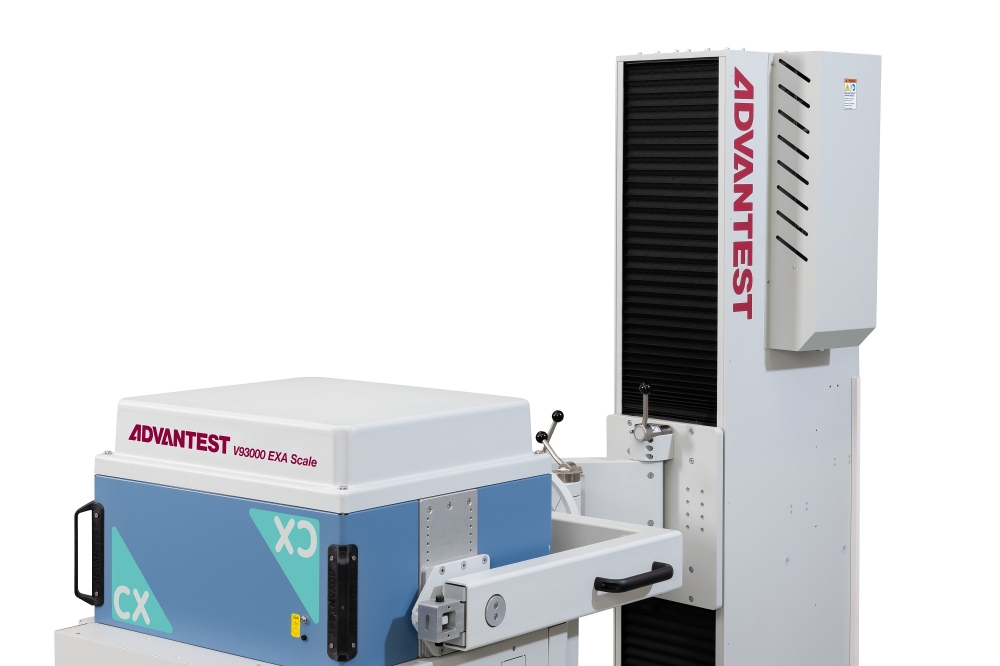

MIRTEC to showcase 3D Semiconductor Inspection Systems

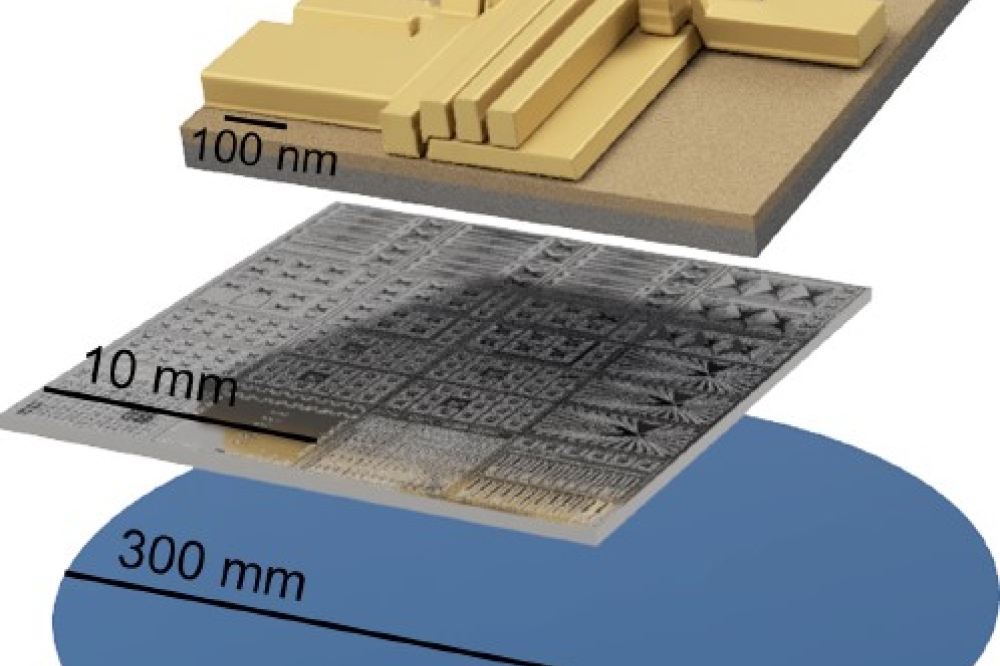

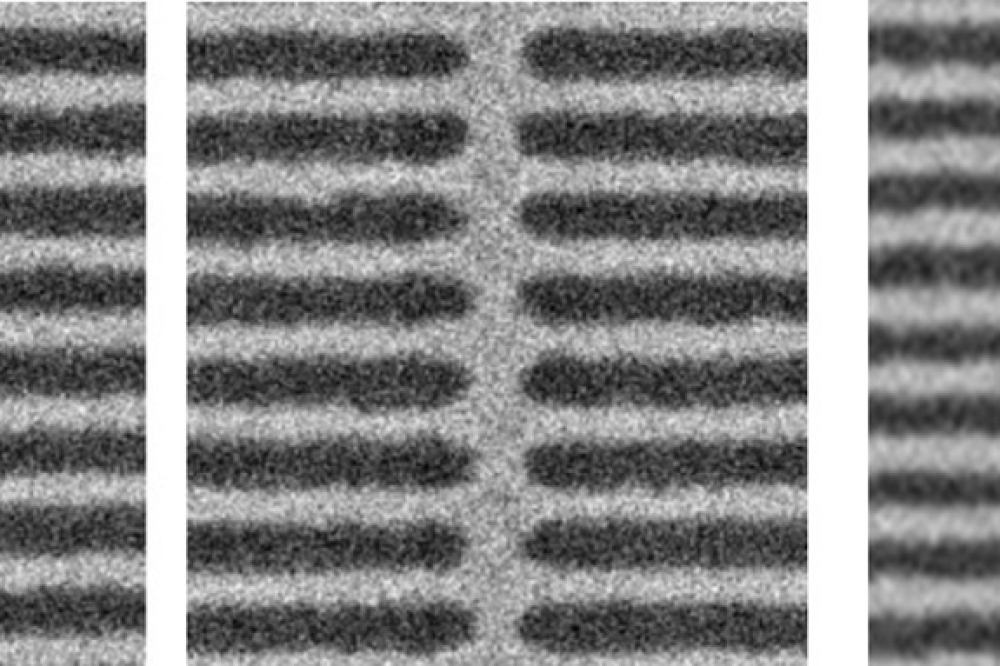

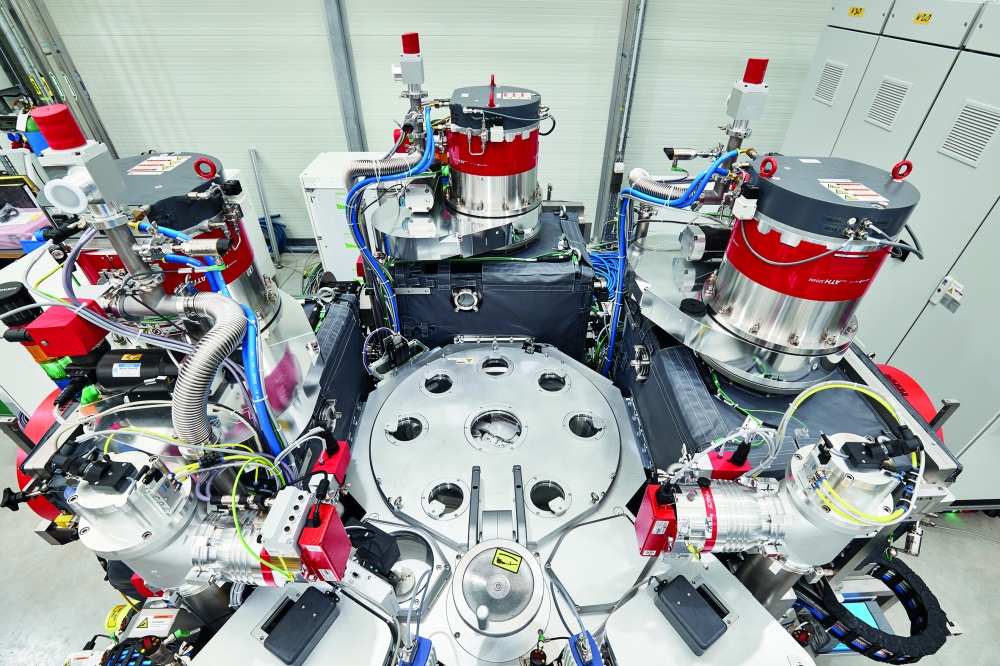

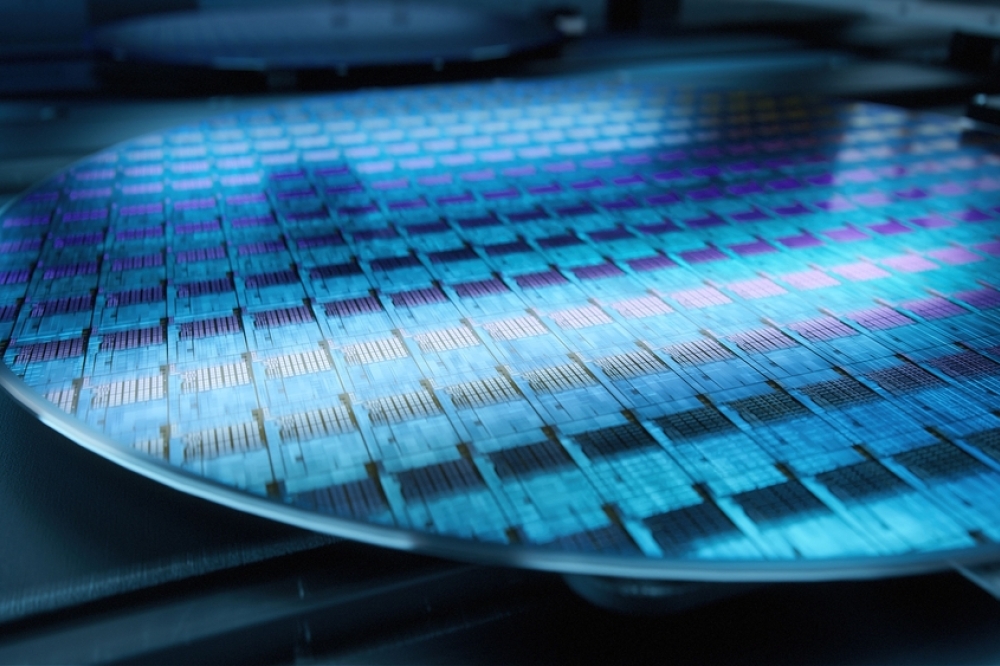

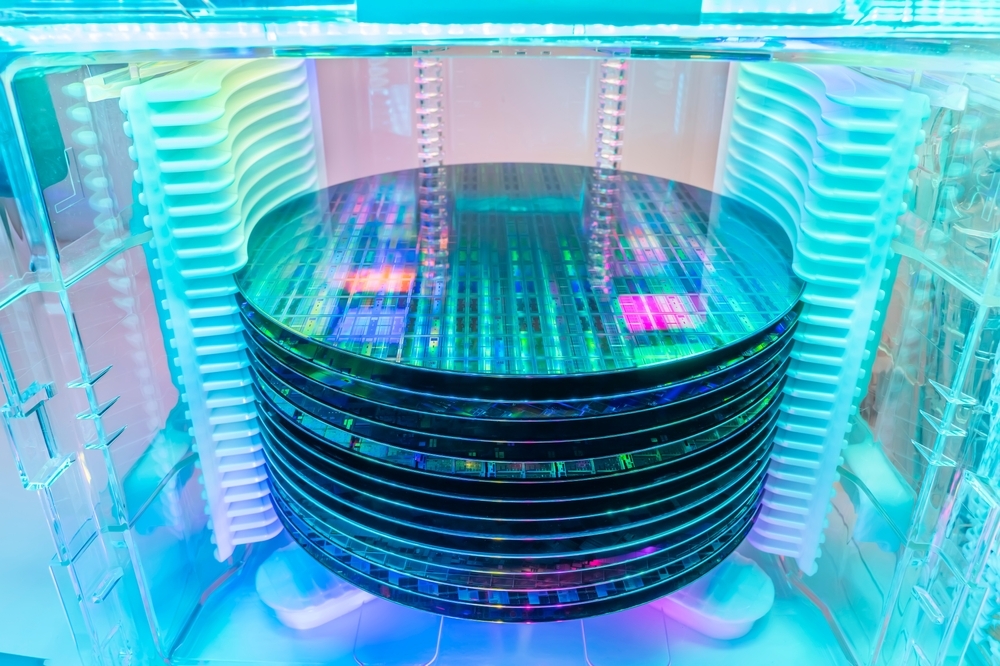

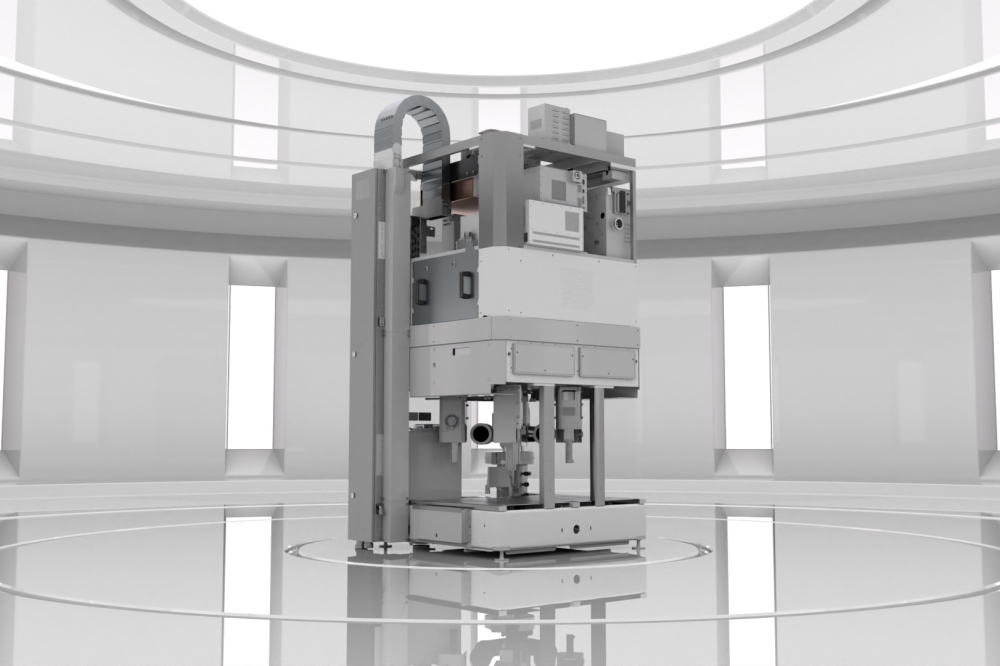

MIRTEC’s Award-Winning MV-9SIP Hybrid 3D Inspection System features exclusive Hybrid System in Package (SiP) Inspection Technology which combines MIRTEC’s 3D Digital Blue Moiré Projection Technology with a High-Resolution Blue Laser Scanner. MIRTEC’s proprietary 25MP CoaXPress vision system is designed and manufactured by MIRTEC for precise inspection of semiconductor post-process. With the combination of a 25MP 7.7㎛ ultra-high camera and the blue light digital moiré projectors, the MV-9SIP finds defects among densely bonded, micro-sized parts such as 01005 size chip array. The Blue Laser Scanner applied to MV-9SIP was developed to measure objects that have surfaces with extreme optical properties such as high reflectiveness or very low reflectiveness. The core idea of this system is to use different inspection methodologies for each item that has different characteristics in a single platform. Lately, the MV-9SIP is not only used to inspect SiP parts, but also solder ball and bump inspection. Since the trend for these inspection items became important recently due to the rise of semiconductor packaging industry.

MIRTEC’s ongoing commitment to innovation has positioned the company as a trusted supplier of advanced inspection solutions for the electronics manufacturing industry. With a focus on high-tech sectors such as automotive, aerospace, and defense, MIRTEC continues to push the boundaries of the inspection technology.