Festo Integrated Automation Solutions streamline semiconductor wafer production

At Semicon West, Festo showcases an interconnected workflow for semiconductor manufacturing, focusing on critical wafer handling and processing. Festo application experts are available for scheduled meetings at this show. (Phoenix Convention Center, October 7-9, Silicon Saxony Pavillion #N1161.)

Festo plays a significant role in the semiconductor industry, providing critical components and solutions for both front-end and back-end processes. The company specializes in pneumatic and electromechanical systems that offer a combination of precision, reliability, and energy efficiency. Festo partners with its customers to improve productivity, increase yield, reduce costs, and enhance sustainability. Festo solutions include precision and gentle handling, highly efficient nitrogen (N2) purge systems, cleanroom-compatible components, digitalization, AI process and predictive maintenance innovations, and industry-leading training and workforce development programs.

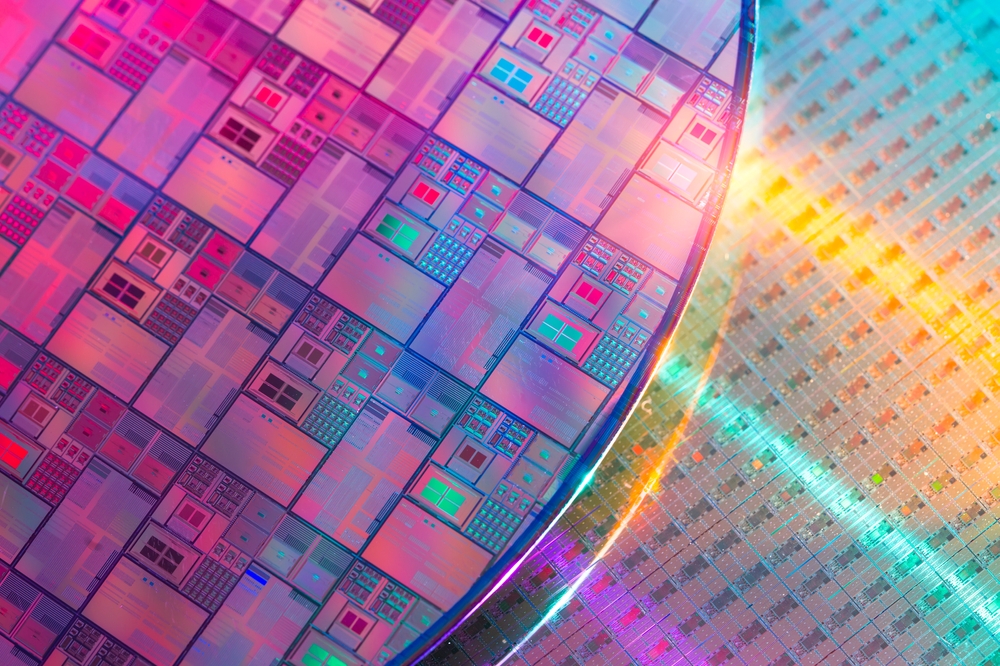

The Central Hub: Wafer Handling and Alignment

The heart of the Festo display at Semicon West is the central hub, where the journey begins with a semiconductor wafer. The hub module features an inverted gantry, a cost-effective alternative to traditional SCARA robots for wafer pickup and transport. The gantry picks wafers from a transport carrier known as a FOUP (Front Opening Unified Pod) and moves them with speed and precision. This provides a fast and reliable way to transfer wafers from storage to the processing line.

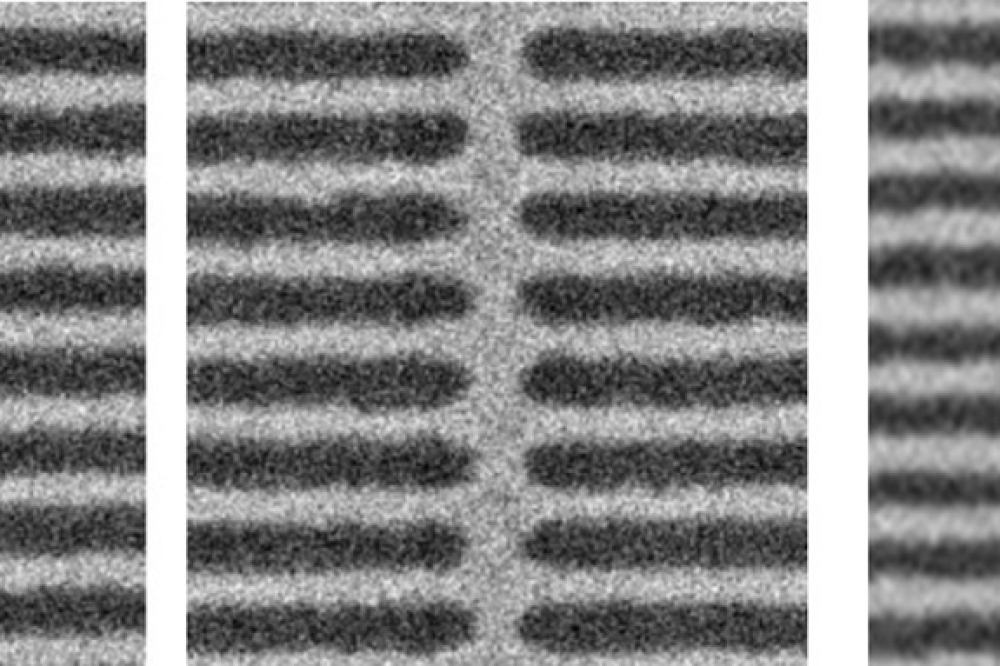

The gantry uses a unique wafer end effector with an integrated wafer aligner. This tool is revolutionary because it combines two functions—gripping the wafer and aligning it perfectly—into a single, compact device. This reduces the complexity of the equipment and ensures the wafer is positioned with sub-micron accuracy before it is transported to the next step in the process.

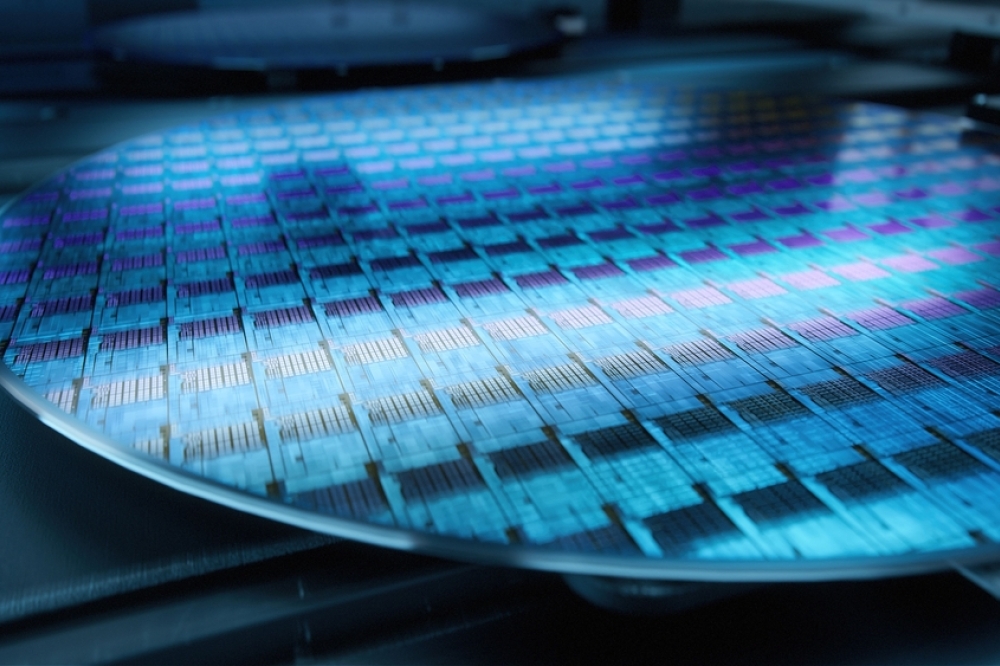

Wet Chemistry and Coating

After being handled by the central hub, the system has the option of moving the wafer to Module 1, which simulates wet chemical processes. The process begins with a FOUP purge, using a Festo MFC (Mass Flow Controller) to ensure the wafer environment is clean and free of contaminants before it's even touched.

The wafer is then loaded onto a coating station. Here, a Festo “suck-back” solution is used in combination with an electric linear axis to precisely move a nozzle across the wafer surface. This system ensures an even coating of chemicals, reducing waste and improving product quality.

Vacuum and Micro-Positioning

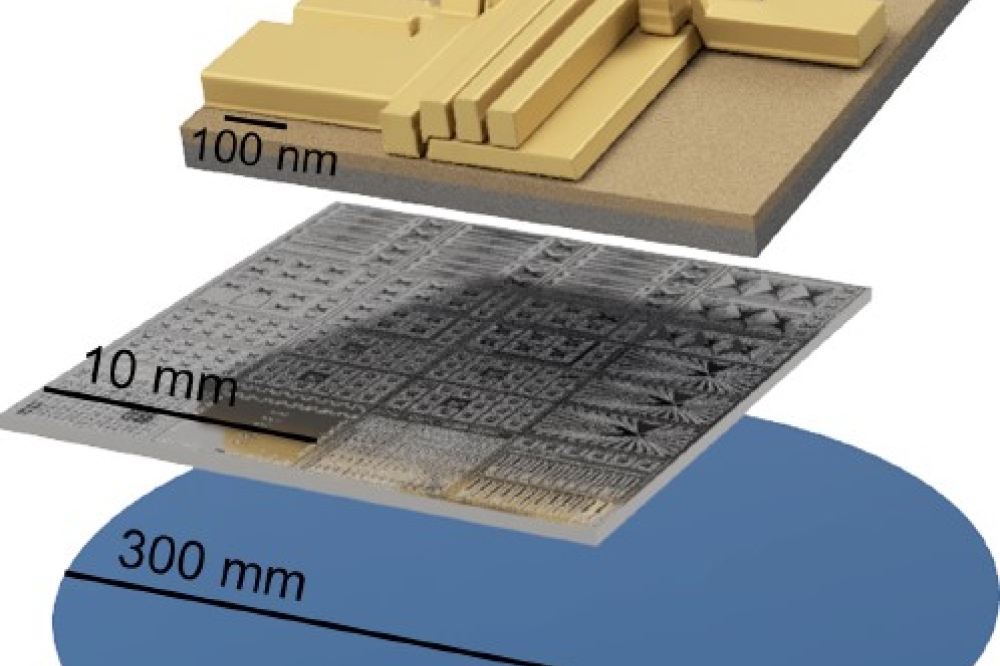

Alternatively, the wafer can be transferred to the wafer handling module (Module 2), which demonstrates processes that occur in a vacuum environment, like dry etching. This module shows how Festo technology can control the opening and closing of slit and gate valves gently, allowing the wafer to transition smoothly into the vacuum chamber.

Inside the chamber, a pneumatic pin lift carefully raises the wafer onto a chuck. The display also highlights a pneumatic micro-positioning system that can place a focus ring with micrometer-level accuracy, demonstrating the fine-tuned control required for advanced semiconductor manufacturing.

The entire display illustrates a seamless process flow: wafers are safely picked, precisely aligned, and then transported to either wet chemistry or a vacuum-based process. This interconnected demonstration shows how Festo’s innovative components—from cost-effective gantries to integrated aligners and precise fluid control systems—work together to enhance throughput, accuracy, and reliability in modern semiconductor production.

Silicon Saxony Pavilion

Showcasing Festo at the Silicon Saxony Pavilion underscores the company’s commitment to global collaboration and technological leadership in semiconductor automation. As Europe’s largest microelectronics cluster, Silicon Saxony represents a hub of innovation, and Festo’s presence there signals its alignment with cutting-edge manufacturing trends and its role in shaping the future of intelligent production. This strategic placement amplifies visibility among key European and international stakeholders, reinforcing Festo’s reputation as a trusted automation partner across borders.