Maximised purity and minimised rinsing times

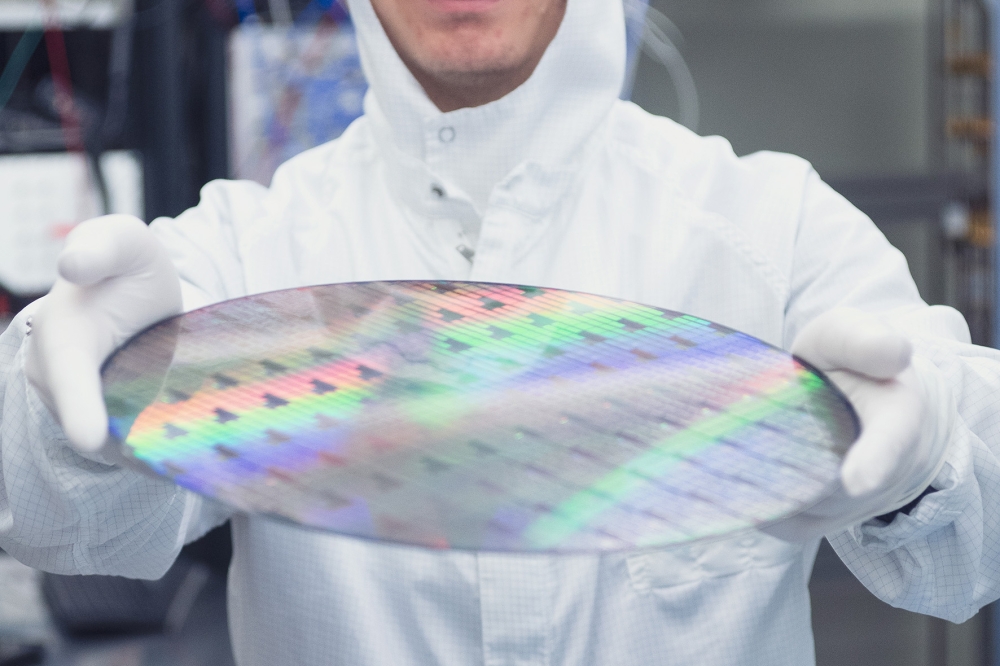

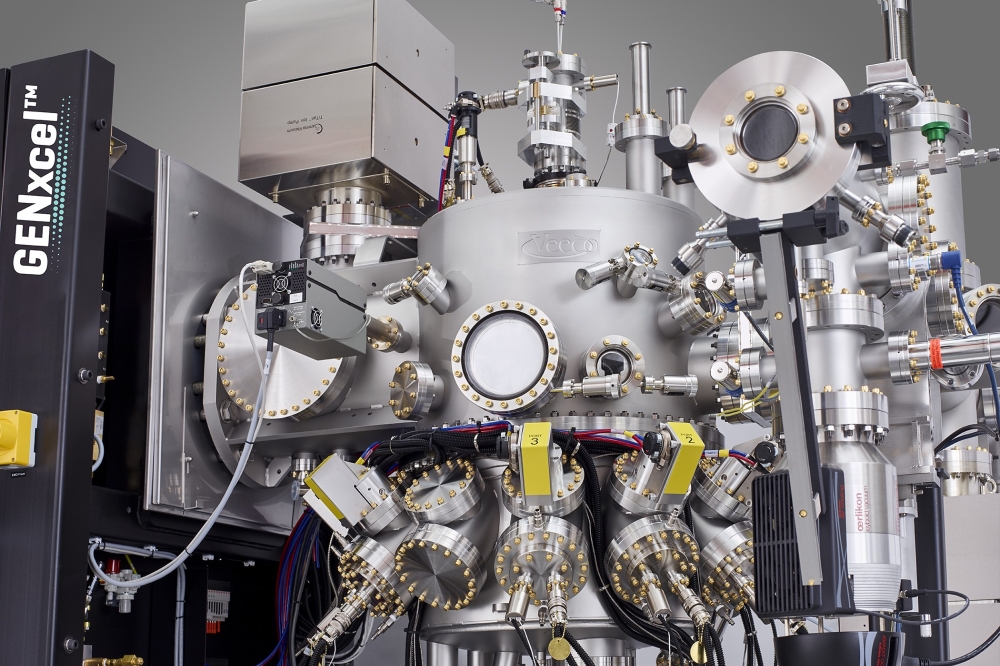

The newly introduced SYGEF Ultra system addresses the needs of the Ångström era by enabling advanced semiconductor manufacturers to stay ahead of developments such as AI, decreasing node sizes and ambitious sustainability goals. GF presented the PFAS-free High Purity PEEK piping system for the first time at the recent UltraFacility Conference in Austin, Texas (US).

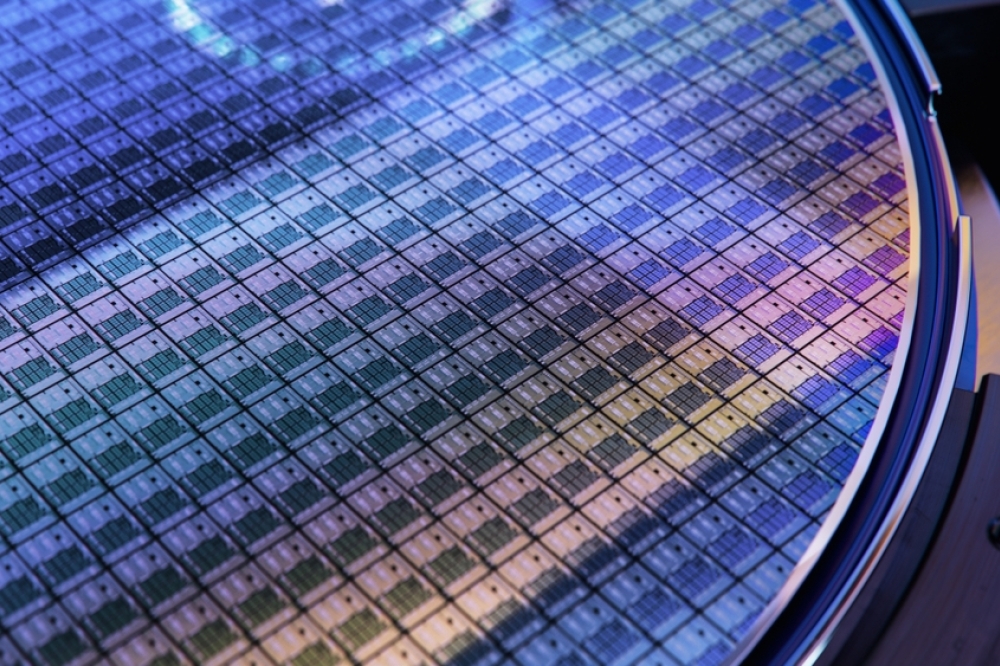

The extreme purity requirements associated with chip technology on an atomic level – where even a single particle can have an impact – are pushing traditional piping materials to their limits. As a result, owners and operators require materials that ensure the highest level of ultrapure water and maximize yield.

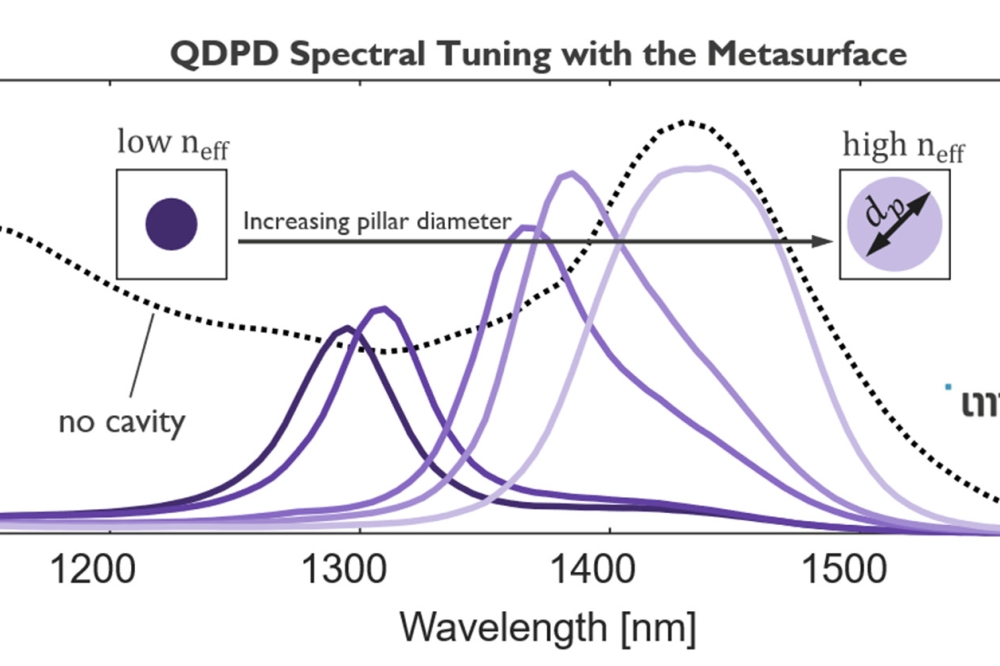

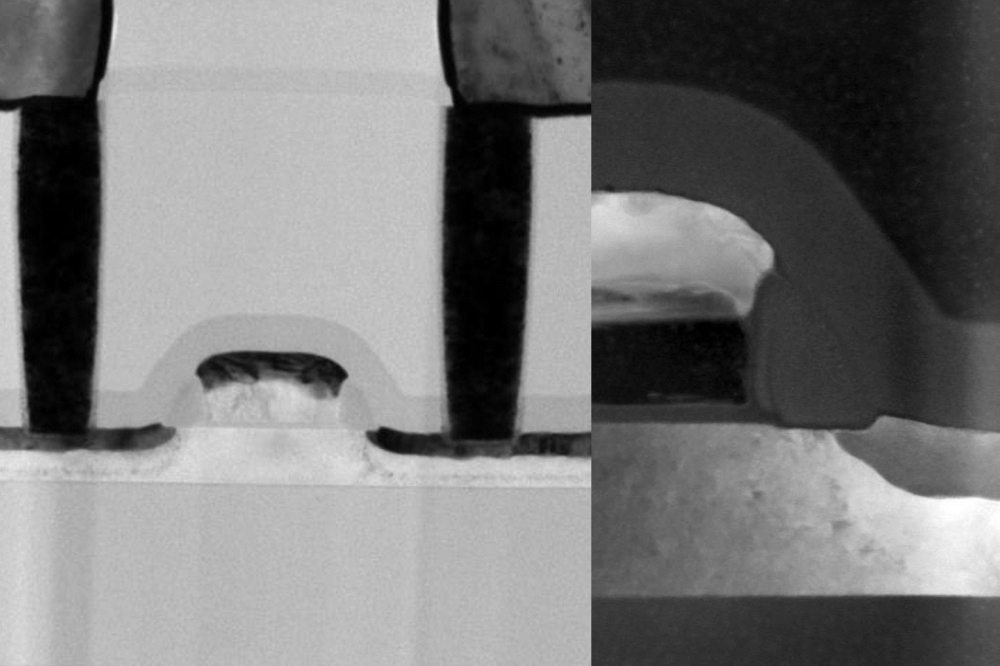

GF developed SYGEF Ultra for hot and ambient ultrapure water systems serving next-generation semiconductor technologies. The system is made of a specific High Purity Polyether Ether Ketone (PEEK), a high-performance polymer that is well-known for its excellent performance in demanding industrial applications. It combines excellent mechanical strength at elevated temperatures as well as impact and chemical resistance with purity levels that exceed SEMI F57 by far. These properties facilitate significantly shorter rinsing times compared to current materials, speeding up SEMI F63 water quality compliance. SYGEF Ultra is also PFAS-free, which addresses increasingly stringent legislation around the world and the sustainability and environmental stewardship goals of end-user companies.

During UltraFacility 2025, from 3 to 5 December in Austin, visitors were able to experience SYGEF Ultra at the booth as well as during the conference. Dr.-Ing. Katrin Wallheinke, Head of Materials Technology, GF Industry and Infrastructure Flow Solutions, introduced the system and discussed its purity performance in relation to industry requirements. In addition, Hanspeter Müller, Senior Application Expert at GF Industry and Infrastructure Flow Solutions, gave a presentation comparing thermoplastic pipe stress modelling and the installation process between PVDF-HP and High Purity PEEK systems.

Wolfgang Dornfeld, President Business Unit APAC, GF Industry and Infrastructure Flow Solutions, emphasizes the importance of SYGEF Ultra: “Semiconductor manufacturers are pushing the boundaries of technology with ever smaller node sizes. With SYGEF Ultra, we can offer an innovative solution for UPW applications that keeps pace with chip development and meets the unique demands of the Ångström era. And thanks to PFAS-free materials, SYGEF Ultra is future-ready.”

SYGEF Ultra is set to be launched in 2026. The high-performance system is bolstered by GF’s complete range of flow solution elements that include pipes, fittings, valves, and welding technology, engineered for ultrapure applications. Refined for the Ångström level, GF’s components for high purity piping systems guarantee the lowest possible particle levels, TOC, anionic and cationic leachout, as well as smooth surface finishes. Extensive jointing technologies that include QA/QC, safe packaging, as well as global engineering and training support, enable reliable installations for more than 25 years of safe operation.