Aerotech expands Two-Axis Laser Scan Head line

The new AGV-CPO laser scan head perfectly balances performance and value for the widest range of laser applications.

Aerotech has launched its AGV-CPO CORE Performance 2-Axis Laser Scan Head. Designed to suit a wide range of laser applications, the AGV-CPO combines dynamics and precision with value. Because the AGV-CPO shares performance capabilities and control hardware with Aerotech’s other premier 2-axis laser scan heads, users get Aerotech’s hallmark precision – and can scale without sacrificing performance or incurring additional control hardware costs.

“Historically, Aerotech's AGV scanners have been users’ first choice for the most demanding laser applications. The AGV-CPO blends our signature high resolution and advanced controls with flexibility and value – enabling users in a wider range of laser applications to scale their processes with minimal effort and cost,” said Bryan Germann, optomechatronics lead at Aerotech.

The AGV-CPO’s CORE performance capabilities include:

Single Controller Architecture - Seamlessly control up to 32 servo and galvo axes with Automation1, Aerotech’s powerful, unified programming environment that simplifies system integration, enables data visualization and produces sophisticated, coordinated motion paths. Features include RS-274 compliant G-code programming, motion lookahead and C-transformations.

Precision and Dynamics - All Aerotech AGV scanners use digital optical encoders and advanced materials to enable industry-leading resolution and dynamics for the most demanding laser applications.

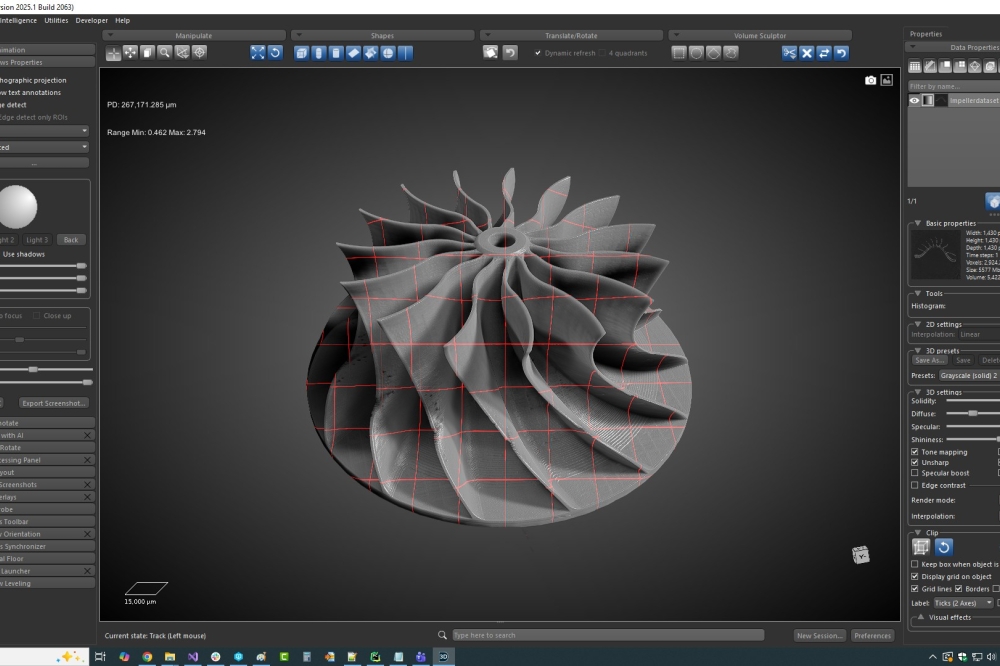

Infinite Field of View (IFOV) – With IFOV, scanner motion seamlessly integrates with servo stages, expanding the effective working area and eliminating stitching errors or complex part repositioning. This improves accuracy and cycle times.

Position Synchronized Output (PSO) – PSO allows for highly accurate laser firing based on real-time position feedback from the scanner mirror position and any coordinated servo stage positions, ensuring the consistent energy delivery demanded by applications like precise cutting, welding, and additive manufacturing.

Ultra-low Thermal Drift and High Process Stability - Integrated motor water cooling and scanner mirror air cooling ensure ultra-low thermal drift, minimizing process drift over time.

The AGV-CPO is appropriate for a range of laser micromachining applications, including:

- Research and Development, particularly for novel ultrafast laser process development

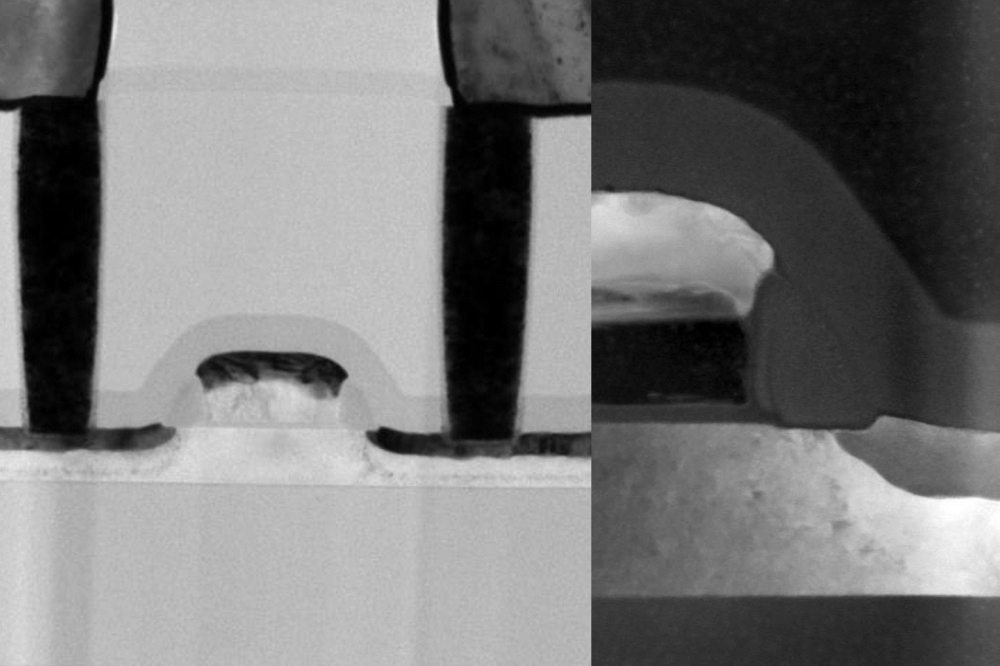

- Medical Device Manufacturing, for micromachining, flat cutting and drilling

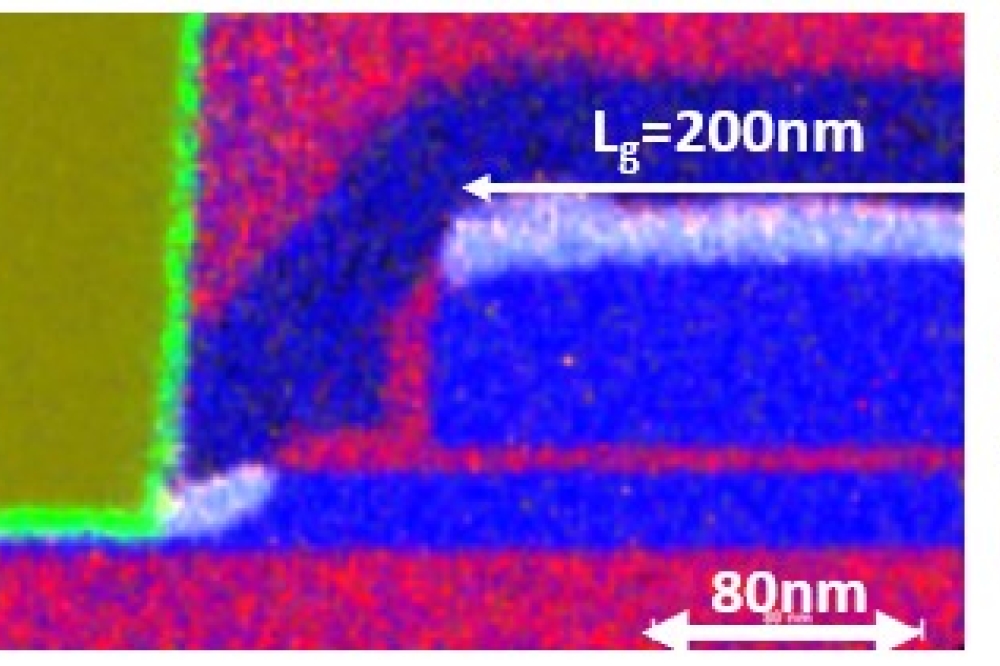

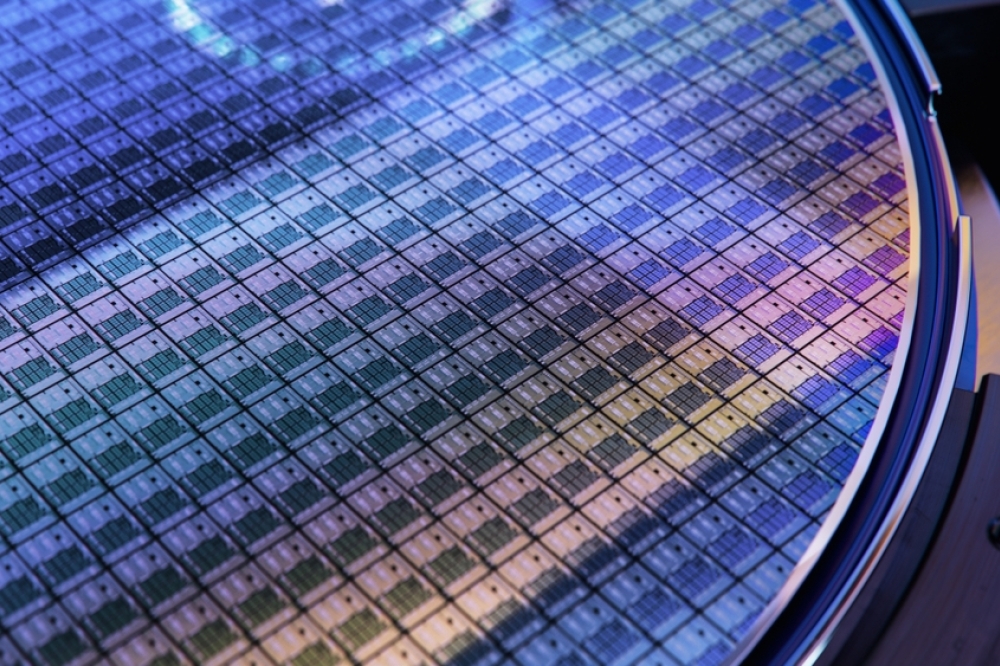

- Electronics Components Manufacturing, for display cutting and PCB drilling

- Semiconductor Component Manufacturing, for TGV drilling and wafer dicing

- Additive Manufacturing, supporting processes like two-photon polymerization