Sintered sinthetic cristoblate

A flux-free, rotary kiln-based thermal process enables direct and continuous conversion of quartz-rich feedstocks into high-purity cristobalite. By applying controlled thermal zoning and residence-time management, the method achieves greater than 95 percent phase transformation while avoiding intermediate tridymite formation and alkali contamination, offering a scalable silica processing route suitable for contamination-sensitive electronic and semiconductor-related applications.

As silicon semiconductor manufacturing pushes toward tighter thermal budgets, longer equipment lifetimes, and stricter contamination control, the upstream processing of silica-based materials has become increasingly consequential. Phase-pure cristobalite offers predictable thermal expansion and high-temperature stability that are directly relevant to quartz-derived components used in crystal growth hardware, semiconductor processing equipment, and advanced electronic materials. This feature is important to the silicon semiconductor industry because it demonstrates a scalable, flux-free method for producing high-purity cristobalite with controlled phase transformation, minimizing alkali contamination risks and enabling consistent material performance under demanding thermal conditions.

This study introduces an innovative rotary kiln-based thermal process for producing high-purity cristobalite from quartz-rich feedstocks. Utilizing a multi-zone sintering strategy without the use of chemical fluxes or alkali additives, the method achieves over 95% transformation efficiency, as validated by X-ray diffraction (XRD) analysis. The process enables rapid conversion of crystalline or amorphous silica into cristobalite while avoiding intermediate tridymite formation. Characterization confirms full phase transformation, purity enhancement, and morphological changes. The scalable, continuous rotary kiln technology presents major advancements over traditional static sintering, making it suitable for ceramics, dental materials, coatings, and electronic applications.

Cristobalite, a high-temperature polymorph of silica, is widely used in ceramics, glass, paints, refractories, and dental materials due to its low density, high whiteness, thermal expansion behavior, and mechanical stability. Traditional production methods rely on static sintering of finely ground quartz at high temperatures for extended durations, which often results in incomplete transformation, high energy consumption, and impurity retention. This article presents a novel rotary kiln-based route that utilizes mineralogical understanding and controlled thermal regimes to achieve efficient, continuous, and industrial-scale cristobalite production.

RAW MATERIALS AND MINERALOGICAL BASIS: - The raw material used is high-purity natural quartz or amorphous silica, optionally pre-treated to remove impurities like Fe2O3, TiO2, and Al2O3. Grain size ranging from 3 mm to 30 mm is suitable for rotary processing. Mineralogically, the transition from quartz to cristobalite involves rearrangement of SiO4 tetrahedra. The cristobalite structure features a cubic or tetragonal lattice and is favored at high temperatures. Avoiding tridymite formation and promoting direct transformation to cristobalite is key to product purity and stability.

PROCESS TECHNOLOGY: -ROTARY KILN-BASED SINTERING.

The process employs a rotary kiln divided into preheating, reaction, and sintering zones with controlled temperature gradients from 1000°C to 1700°C. Feed materials are continuously charged and sintered at 1550–1650°C for durations sufficient to enable structural conversion. The tumbling motion ensures uniform heat exposure, crystal nucleation, and efficient transformation.

Thermal-Driven Transformation (No Chemical Additives)

Unlike conventional flux-assisted processes, this method relies solely on optimized thermal control and feedstock morphology to induce quartz-to-cristobalite transformation. No alkali fluxes or chemical catalysts are used. Careful control of residence time and thermal gradient ensures crystalline purity and morphological uniformity.

Thermal-Driven Transformation (No Chemical Additives)

Unlike conventional flux-assisted processes, this method relies solely on optimized thermal control and feedstock morphology to induce quartz-to-cristobalite transformation. No alkali fluxes or chemical catalysts are used. Careful control of residence time and thermal gradient ensures crystalline purity and morphological uniformity.

Phase Transformation Mechanism

The transformation pathway involves:

• Quartz → High-Quartz → Cristobalite

• Bypassing of tridymite via kinetic control and optimized thermal regime

• Crystal growth through surface nucleation and internal restructuring

• Transformation achieved without external fluxing agents or alkalis

This kinetic pathway is confirmed by comparative thermal and structural analysis.

Results and Characterization

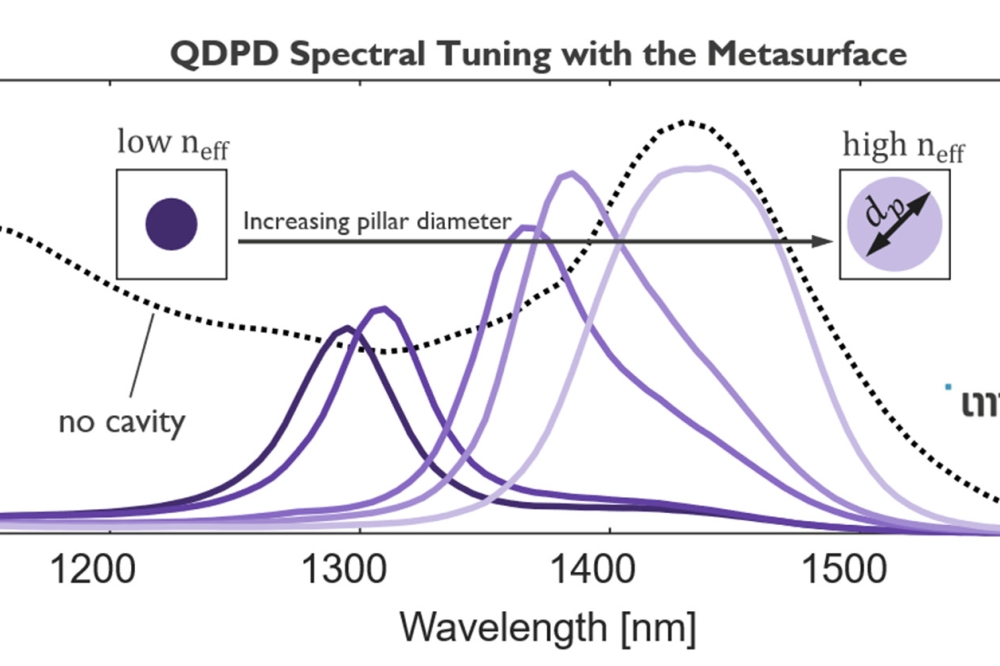

XRD Analysis

X-ray diffraction (XRD) of the sample labeled B 0.5 sintered at 1600°C reveals complete cristobalite formation, matching the international reference pattern (e.g., ICDD PDF 04-002-6313). No residual quartz or tridymite peaks were observed, confirming phase purity.

Morphology and Microstructure.

Cristobalite crystals exhibit a dense, fine-grained microstructure under SEM, showing improved homogeneity and particle bonding. This favors mechanical strength and application-specific performance.

Chemical Purity and Brightness.

Final sintered products show reduced levels of Fe2O3, Al2O3, and TiO2, supporting higher brightness and whiteness, desirable for optical and ceramic applications.

Applications

• Paints & Coatings: Whiteness and matting properties make it ideal as a filler.

• Catalyst Carriers: Cristobalite’s porosity and thermal stability suit chemical catalysts.

• Refractories and Ceramics: Improved thermal shock resistance and high-temperature performance.

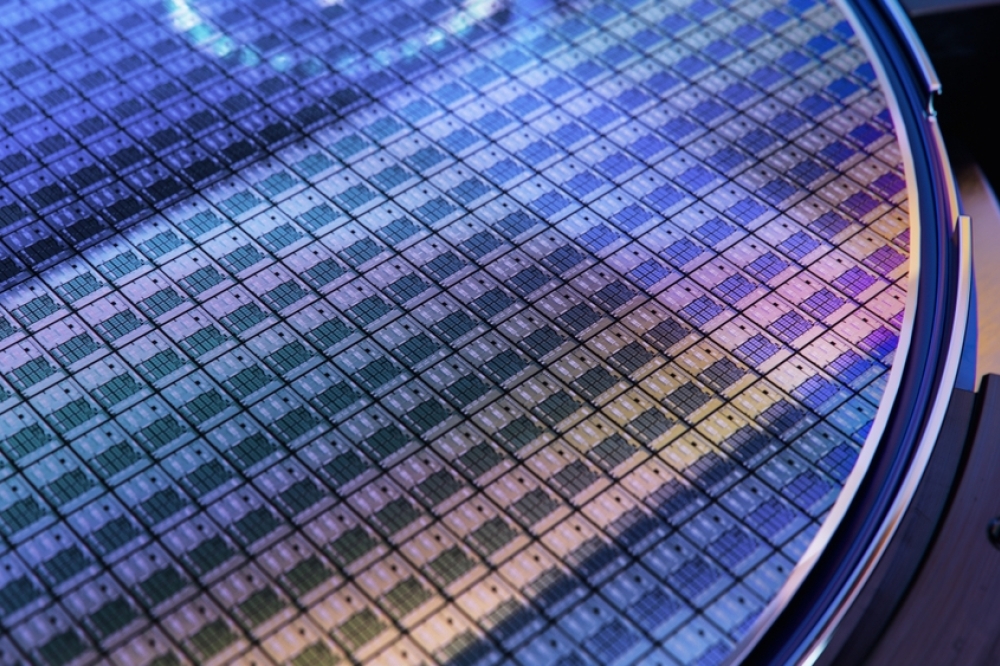

• Semiconductor Glass & Composites: Silica backbone supports electrical and structural applications.

Technical Advantages

• High crystallinity (>95%) with minimal impurities

• Avoidance of tridymite and devitrification

• Continuous, energy-efficient rotary kiln operation

• Suitable for both crystalline and amorphous silica inputs

• Flux-free, environmentally clean process with high scalability

CRISTOBALITE PRODUCTION PROCESS DASHBOARD

This dashboard presents mock data simulating the relationship between processing temperature, Cristobalite formation, quartz reduction, whiteness index, and grain size distribution.

Conclusion

This work demonstrates an advanced method for cristobalite synthesis using rotary kiln technology and flux-free sintering. The method achieves complete quartz transformation under optimized thermal regimes without the use of alkalis or additives, offering industrial viability, enhanced product quality, and broad application potential. The process sets a new benchmark for mineral-based silica conversion.

Contact details: raatech12@rediffmail.com