SK hynix LPDDR5X achieves ASIL-D

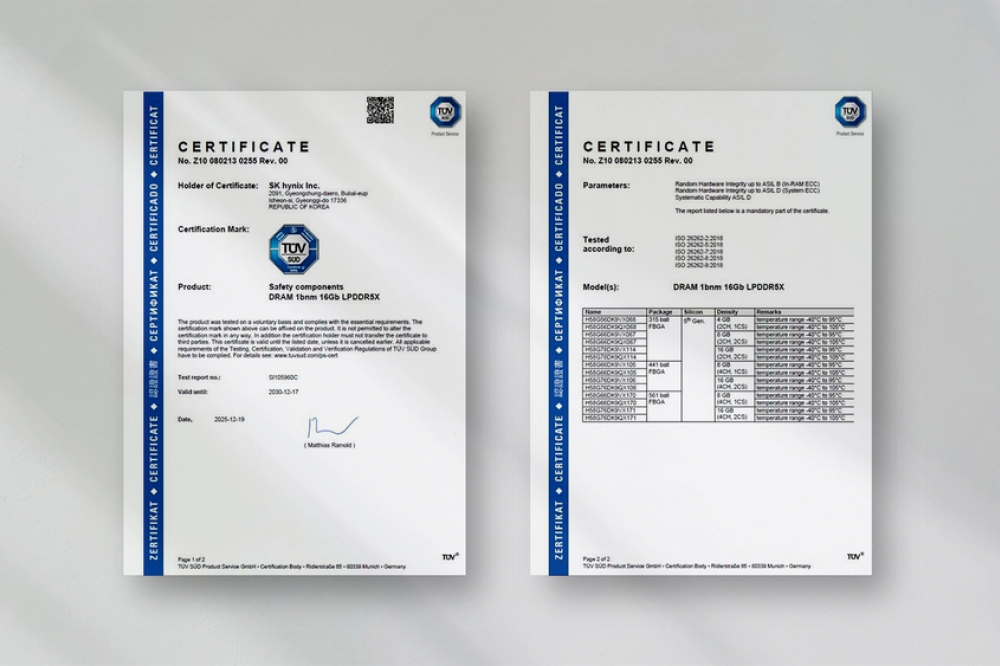

SK hynix has achieved the Automotive Safety Integrity Level D (ASIL-D) certification for its latest LPDDR5X automotive DRAM, the highest safety rating under the ISO 26262 international standard for functional safety in vehicles. ASIL-D is the most rigorous safety integrity level for automotive systems whose functional safety is critical to human life. Global functional safety certification body “TÜV SÜD” grants the certification following a comprehensive assessment of the entire development and production framework, including the development process, product design, verification, and quality management systems.

With this certification, SK hynix has officially validated its technical competitiveness in the automotive memory market by simultaneously satisfying requirements for high performance, safety, and reliability.

The Essence of SDVs and Autonomous Driving: Verification of Processes and Products

The ASIL-D certified LPDDR5X automotive DRAM meets the demand for high-performance, low-power, and high-reliability in next-generation automotive systems such as ADAS(1), autonomous driving, and in-vehicle infotainment (IVI). Specifically, the chip’s competitive edge is that it functions as the vehicle’s essence, processing massive amounts of data stably and minimizing the possibility of system errors in an SDV(2) environment.

1ADAS (Advanced Driver Assistance Systems): Advanced systems that assist driving and prevent accidents by monitoring surroundings via sensors (radar, LiDAR, etc.).

2SDV (Software Defined Vehicle): A vehicle where hardware is controlled and managed primarily through software.

As the proportion of electronic and electrical systems in vehicles increases, the key metrics for automotive DRAM competitiveness are shifting from simply increasing performance or lowering defect rates to securing functional safety. Consequently, a chip’s ability to integrate safety mechanisms that predict and control potential failures from the design stage is emerging as a critical differentiator in the market. In other words, actively developing and applying safety mechanisms and gaining design competitiveness will be critical to securing a dominant position in the market.

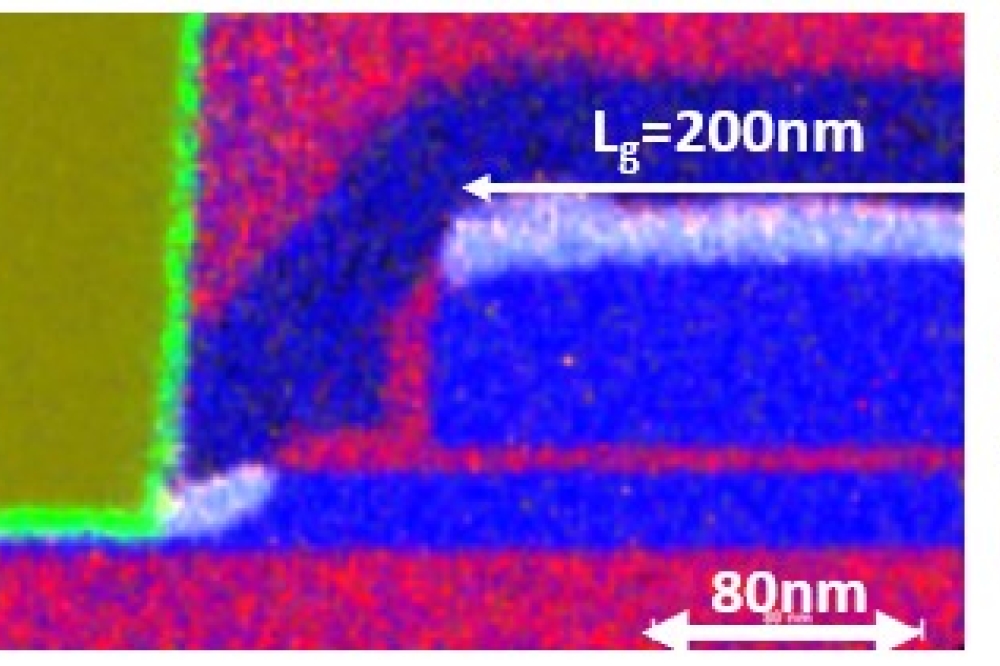

SK hynix has also achieved ASIL-D certification by implementing a design for its LPDDR5X-based automotive DRAM that balances ▲stable data reliability even in extreme environments ▲fault notification & self-diagnostic/repair functions, and ▲ultra-high bandwidth & low-power characteristics.

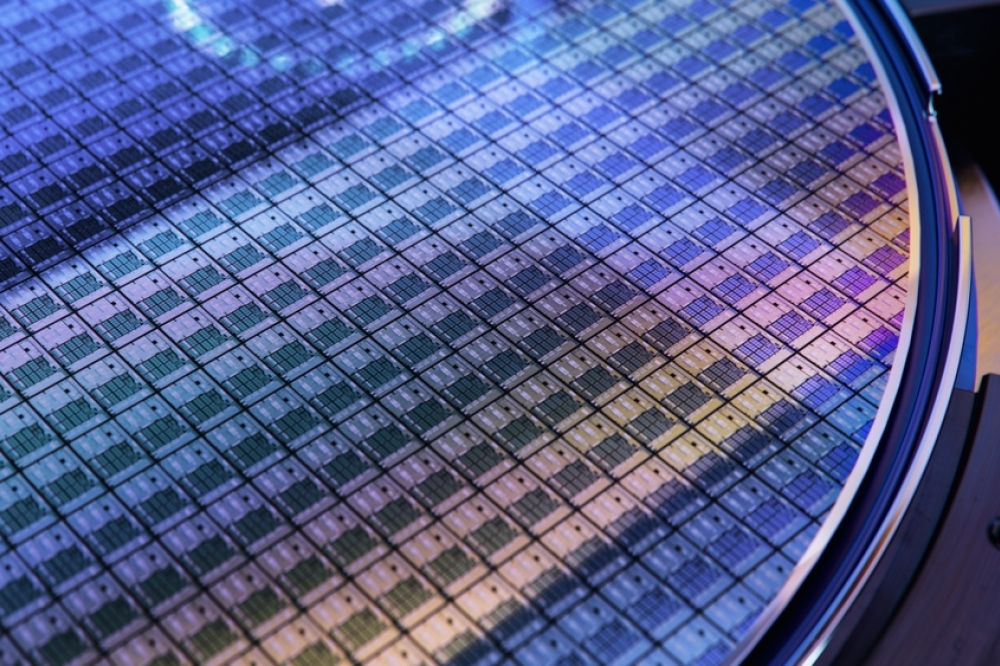

SK hynix’s ASIL-D certified LPDDR5X

During the evaluation process, TÜV SÜD comprehensively verified not only the functional safety performance of the LPDDR5X but also its ▲safety architecture & design concepts ▲error prevention/detection/diagnosis mechanisms ▲development & verification processes and ▲the overall quality management system. As a result, the certification affirms that SK hynix’s development, verification, and quality processes align with global automotive industry standards.

With this ASIL-D certification, the chipmaker plans to continue providing memory solutions that customers can rely on in the autonomous vehicle and future mobility sectors.

Swift Response to Customer Needs: Obtaining ASIL Certification with Great Speed

The driver behind SK hynix’s pursuit of ASIL-D certification is the rapid restructuring of the automotive industry toward SDVs and autonomous driving. With electronics now accounting for over 40% of a vehicle’s composition, system reliability has become a core factor directly linked to passenger safety. Accordingly, the ISO 26262 functional safety certification has evolved from a nice-to-have to a mandatory requirement.

ISO 26262, established by the International Organization for Standardization (ISO) in 2011, is an international automotive functional safety standard that aims to prevent accidents caused by failures in electrical and electronic systems within vehicles.

Its importance was further elevated in 2018 with the addition of specific requirements for automotive semiconductors.

ASIL (Automotive Safety Integrity Level), a key metric of this standard, assigns grades from A to D based on a combination of three risk factors: Severity, Exposure, and Controllability(3). While standard dashboards in vehicles typically require ASIL-B, autonomous driving control systems mandate the highest level, ASIL-D. SK hynix proactively responded to these customer requirements by establishing its LPDDR5X automotive DRAM lineup and completing ASIL-D certification in a timely manner.

3 Severity: the degree of injury to a person in the event of a part or system failure. Exposure: an environment that causes a part or system failure. Controllability: the degree to which the risk can be avoided in the event of a part or system failure.

Core Strategy for Achieving Highest Level Certification Integrated into the Design

To achieve ASIL-D, a product must meet predictive and responsive requirements for both systematic failures and random faults. Systematic failures refer to issues that can occur during development, design, process, or verification. Random faults refer to inevitable malfunctions caused by degradation during use, even after applying and verifying the latest technologies.

These failures typically occur during the “useful life” of a product which is the period excluding the Infant Mortality Phase and Wear-Out Phase. Since failures of automotive products can lead to loss of life, failure prediction is a core consideration in the ASIL grading process.

To control systematic failures, SK hynix established a Functional Safety Management (FSM) system, managing the entire process from development to mass production through standardized protocols. The FSM systematically documents all stages from defining customer requirements to design, verification, and mass production management, records all decisions and verification results during the development process, and thoroughly applies verification methodologies required according to ASIL level.

To address random faults, SK hynix built a management system based on metrics such as SPFM (Single Point Fault Metric), LFM (Latent Fault Metric), and PMHF (Probabilistic Metric for Hardware Failures)(4). ASIL-D requires strict thresholds: SPFM ≥ 99%, LFM ≥ 90%, and PMHF ≤ 10 FIT5.

4 Random Faults: unavoidable failures that occur due to product deterioration during use. Single-Point Faults (SPFs): defects that can cause an accident with just a single defect. Multiple-Point Faults (MPFs): defects that can cause an accident with two or more defects occurring simultaneously.

5FIT: The standard for one failure in one billion hours.

SK hynix implemented safety mechanisms from the circuit and device design stages to meet these standards, ▲including Error Correction Code (ECC) for data error rectification ▲dual-fuse mechanism for defect response and ▲fault notification functions based on error severity diagnosis.

Automotive Memory Strategy Expanding Beyond Technological Competitiveness to ‘Trust’

By systematically analyzing key factors for ASIL attainment and responding proactively, SK hynix successfully secured the highest level of certification. This achievement is more than a technical milestone; it serves as a significant indicator that the company’s automotive memory business strategy is evolving in the right direction.

By obtaining the functional safety certification most prioritized by global automakers when selecting a product, SK hynix has secured practical competitiveness for future business expansion of automotive memory and the strengthening of customer trust.

SK hynix plans to continue growing as a key memory Chip company leading the future mobility era, based on higher stability, more advanced technology, and more rigorous quality standards.