Preventing liquid cross-contamination in semiconductor manufacturing

Producing high-purity wafers via the CMP process is a critical application and the halting of harmful slurry-DIW cross-contamination and back-flow can be optimised with the Malema Interconnect Interlock Device.

By Jay Rajagopalan, Malema

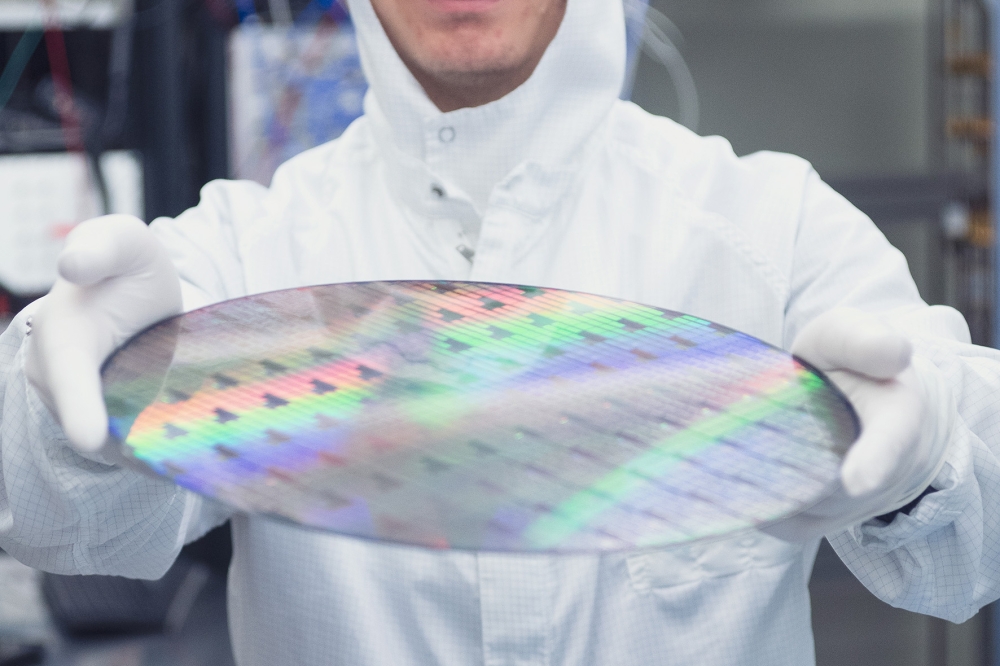

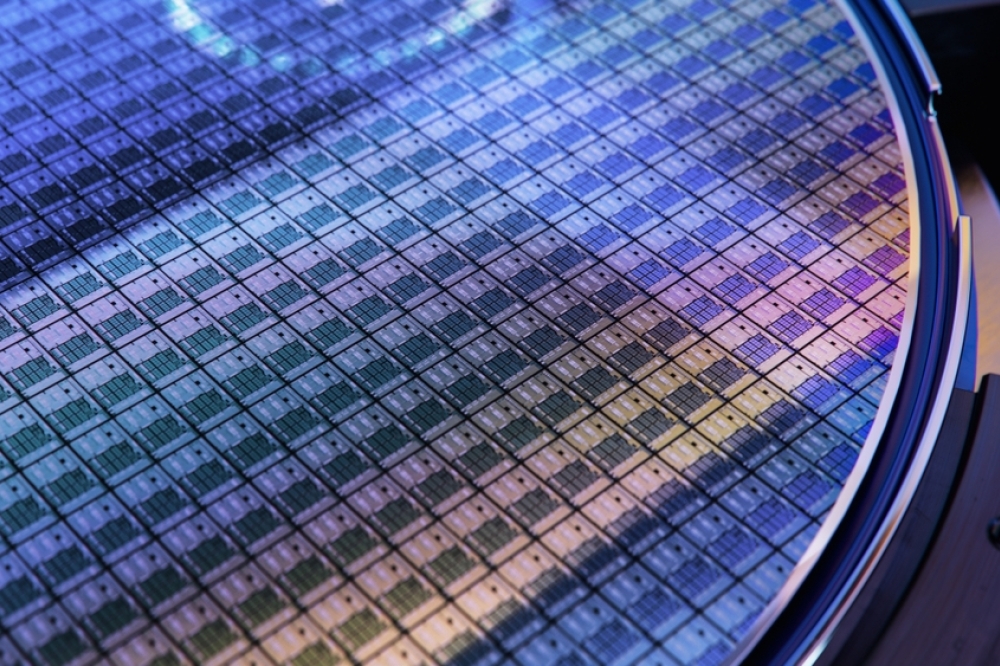

Chemical Mechanical Planarization, or CMP, also known by some of its practitioners as Chemical Mechanical Polishing, is a stage in the semiconductor-manufacturing process where the surfaces of an integrated circuit – otherwise called a “wafer” – are smoothed and flattened via chemical and mechanical forces.

The CMP process requires the use of a colloidal chemical slurry that contains nano-sized abrasive powders. The slurry is pumped over the surface of the wafer with a polishing tool, which removes excess material and imperfections from the wafer’s exterior, resulting in a uniformly smooth and ultra-flat, or planar, finish. In the final stage of the CMP process, deionized (DI) water is sent through the polishing tool in order to wash away any remaining chemical slurry from the wafer’s surface before the next wafer in the production line is treated.

To optimize the CMP process, it is imperative that the dedicated supplies of chemical slurry and DI water not be allowed to commingle; allowing this to happen will adversely affect the slurry’s ability to deliver the demanded level of smoothness to the wafer’s surface. However, some semiconductor manufacturers noticed slurry contamination with DI water within

their CMP systems, which led to lost wafers, overall reduced yields and unwanted repair, replacement and cleanup costs.

This article will illustrate how this phenomenon was confronted and, eventually, solved through the creation of a breakthrough technology: the Malema™ Interconnect Interlock Device (MIID-1000), which has been designed to specifically prevent cross-contamination of the CMP slurry and DI water.

One of the differentiating advantages of the Malema

MIID-1000 is that it can be retrofitted onto existing CMP polishers as a

drop-in replacement for the existing slurry-supply manifold. Malema

streamlines this retrofit process by including all of the needed parts

in a replacement kit with a single part number.

The challenge

As mentioned, the overarching challenge of the CMP process comes from the aggressive nature of the chemicals that are used, as well as the abrasiveness of the very-fine grinding particles found in the polishing medium. This makes the flushing away of the used chemical slurry with DI water critical to the success of the CMP operation.

At the beginning of the process, however, the chemical slurry must not be contaminated by any other type of liquid. If this occurred, its ability and effectiveness in producing the ultrasmooth and ultra-flat wafer surface would be compromised.

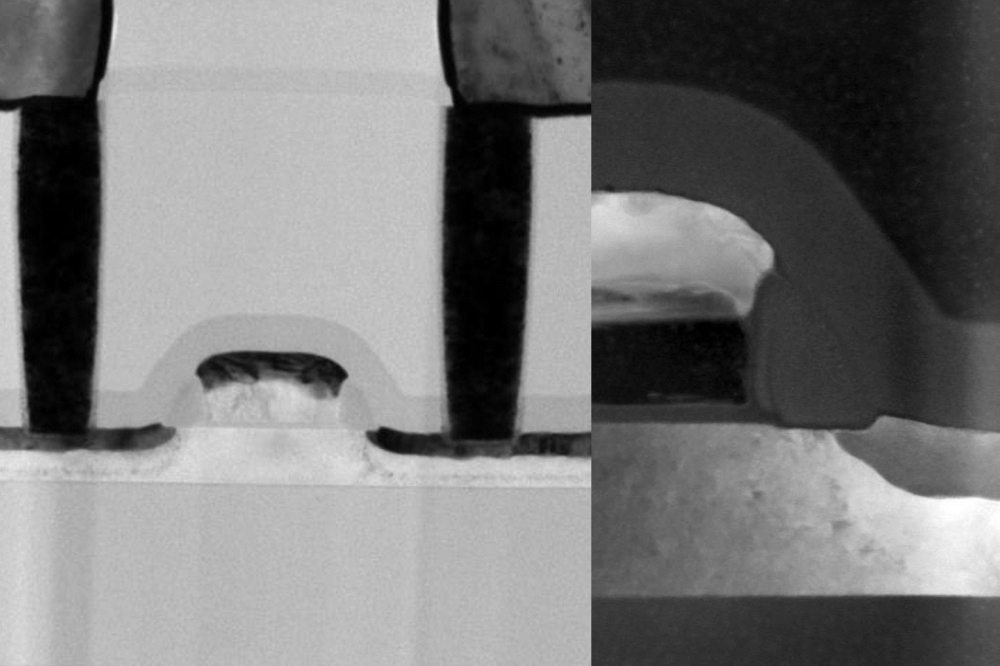

The prevention of this unwanted occurrence has traditionally been achieved by using a three-way diverting valve designed to alternately deliver the chemical slurry and DI water for the CMP process. Operators were discovering, though, that there were times when the polishing tool requested slurry that DI water was delivered instead and vice versa.

An investigation into what was causing this problem also revealed that DI water was diluting the chemical supply and, again, vice versa. At this point, the entire semiconductor-manufacturing system would need to be shut down for cleaning.

A thorough, top-to-bottom examination and review of the CMP system revealed that the root cause of the slurry/DI water cross-contamination was unexpected and intermittent reverse liquid back-flow or internal bypass leaks in the three-way valve that were occurring during certain operating conditions experienced by the polishing tool. Finding this hiccup in the CMP process was difficult because while the valves were indeed malfunctioning, they were not actually being damaged at the same time, so they would often times return to normal function for a period of time before malfunctioning again.

Identifying the problem was also made more problematic by the simple mechanical fact that, to some degree, all valves will leak. The job for the user is to determine what is an acceptable leak rate for the application in which the valves will be used. Further complicating the problem is the volume of slurry or DI water that was lost during back-flow or reverse bypass-leak conditions could be less than 5 milliliters per minute (0.17 ounces per minute), a miniscule amount that can be extremely difficult to detect, yet one that still possesses the ability to contaminate or dilute the CMP processes’ cross-connected liquids.

This cross-contamination via back-flow and bypass leaks can be prohibitively costly for the semiconductor manufacturer since it will typically result in the cessation of the production process and long periods of downtime.

These unplanned shutdowns to repair or replace leaking components and clean up contaminated plumbing systems will both adversely affect the operation’s overall financial performance and make meeting tight delivery schedules virtually impossible.

All of this meant that a solution to the problem would have to satisfy two things: 1) detect when a back-flow or a reverse-bypass leak was occurring in the three-way valve and 2) prevent these events from happening.

The solution

Recognizing the urgent need for a solution to the leaking three-way valve quandary, Malema, Boca Raton, FL, USA, a brand of PSG®, Oakbrook Terrace, IL, USA, a Dover company, began searching for ways to either prevent the leaks from occurring or develop a next-generation solution

to the conundrum.

With over 20 years of experience supplying ultrasonic- and Coriolis-based flow measurement and control solutions to major semiconductor equipment manufacturers, the engineering team at Malema understood the industry’s exacting requirements for cleanliness and reliability.

In the search for a leak-halting solution, Malema engineers tested a variety of methods that could potentially prevent the leaking-valve condition.

These included the incorporation of low-flow uni- and bi-directional flow switches, flow meters, and pH and conductivity meters. While these pieces of equipment were able to detect back-flow and bypass leaks in the three-way valves, they were only able to do so after the slurry or DI water supplies became contaminated, which compromised the CMP process.

The ”eureka” moment for the Malema research team came when they determined that a “double block-and-bleed” (DB&B) valve arrangement would prevent reverse bypass leaks. DB&B is a piping configuration that anticipates leaking valves, but provides absolute protection against their precarities by placing dedicated isolation valves upstream and downstream of a third vent valve on both the CMP slurry and DI water lines.

This double containment between the two liquid-supply lines ensures that no amount of back-flow or bypass leaks will bleed through to the other side of the valve block. Instead, any CMP slurry or DI water that does leak is vented out of the polishing tool before it reaches the point of use (POU). In laboratory tests where all of the valves were actually forced to leak, the DB&B configuration prevented any of the leaked liquid from working its way downstream to the POU or back upstream to the supply lines.

These features were incorporated into the patented Malema Interconnect Interlock Device (MIID-1000) By-Pass Leak Detection and Prevention System, which has been designed specifically to protect against liquid back-flow and internal bypass leaks. This capability is created via a manifold of pneumatically actuated valves that operate in a coordinated fashion in order to ensure that CMP-liquid supplies cannot be contaminated before use or during the actual CMP process.

A built-in leak sensor in the Malema MIID-1000 enables it to prevent

cross-contamination from occurring by sounding a warning when a

potential back-flow event that will mix the CMP slurry with DI water

could be imminent.

Key features of the MIID-1000 include:

• All wetted components are constructed of high-purity PTFE (modified) and PFA

• Non-wetted surfaces of PFA and PVDF

• Other materials used: FKM seals, ECTFE-coated stainless steel, polypropylene, nylon and acetyl

• Media-pressure range from 0 to 80 psig (0-5.5 bar)

• Pneumatic-actuation pressure range of 60 to 120 psig (4.1-8.3 bar)

• Media-temperature range of 0ºF to 265ºF (-17.7ºC-130ºC), excluding phase changes

MIID standing guard cleanroom level sub

• Ambient-temperature range from 0ºF to 150ºF (17.7ºC-130ºC), with no frozen liquids allowed • Critical Value characteristic: Cv = 0.8

• Field-configurable inlet connections –with either 1/4- or 3/8-inch flare nipples – that allow for simplified retrofit installation and reduced inventories

• Minimal had loss

• Built-in leak detection and monitoring

• Built-in optical valve-position sensing

• Valve components tested to more than 10 million cycles for DI water and more than 2 million cycles for SS-12 slurry

To simplify the incorporation of the MIID-1000 into a CMP system, Malema integrated the supply lines for the CMP slurry and DI water into a single block. This combines the leak-detection and drain-management features of two DB&Bs in one easy-to-handle and install console.

Additionally, Malema has created MIID-1000 retrofit kits – which can be installed by an experienced technician in as little as two hours – that include all components needed to upgrade an existing CMP system.

The retrofit kits place the MIID-1000 into a watertight programmable logic controller (PLC) enclosure. This allows the system’s existing plumbing and pneumatic signals to be repurposed to manage the MIID-1000’s functions.

Since this process makes the operation of the MIID-1000 completely transparent to the system’s host-tool controller, no adjustment to the host tool’s software is needed. Finally, all of the electrical connections between the MIID-1000 and the PLC are fully connected. This enables any leak-warning signals generated by the MIID-1000 PLC to be communicated to the existing user-input channels on the CMP polishing tool.

Conclusion

The use of three-way valves in CMP systems in semiconductor manufacturing had been accepted, as had the fact that, at some undetermined point, those valves would experience liquid back-flow or internal bypass-leak conditions. The problem with this habitual “cost of doing business” with three-way valves was unpredictable cross-contamination of the chemical slurry and DI water that are the lifeblood of the CMP process.

The results when this happens are not pleasant or profitable: shutdown of the semiconductor-manufacturing process; excessive downtime to rectify the problem; and the accumulation of ancillary repair, replace and cleanup costs that will have a deleterious effect on the operation’s bottom line.

To put an end to this untenable situation, Malema worked to find a solution, achieving it with the creation of the Malema Interconnect Interlock Device. This innovative device allows semiconductor manufacturers to replace their OEM-supplied and mis-performing three-way valves with a DB&B-based solution that completely eliminates liquid back-flow and internal bypass leaks.

The ultimate result is optimized wafer production that can be a boon to the semiconductor-manufacturing operation’s bottom line.