ZEISS SMT extends global footprint in actinic mask qualification

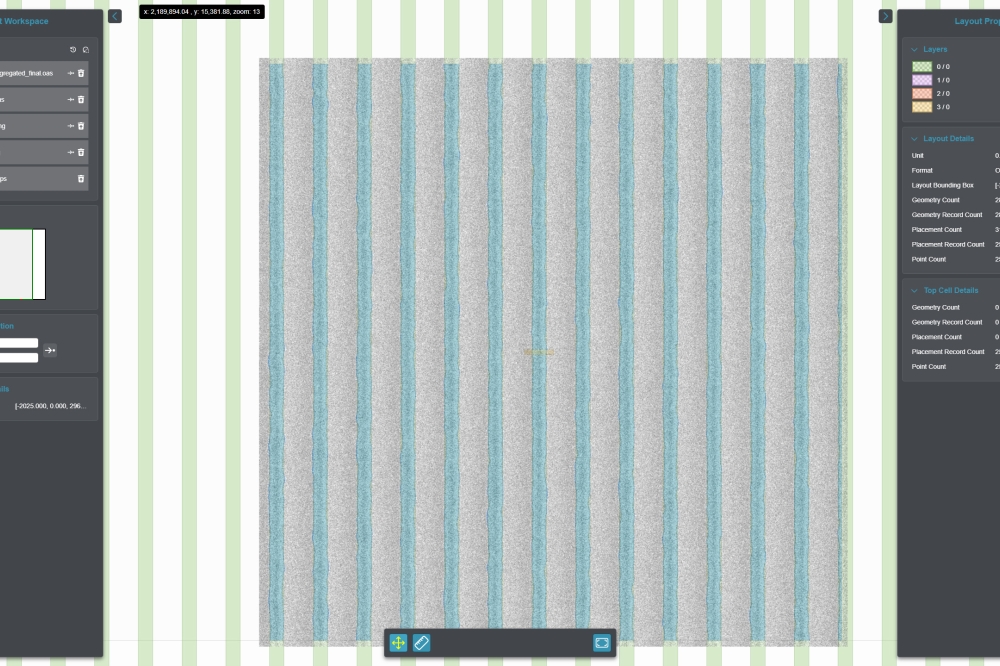

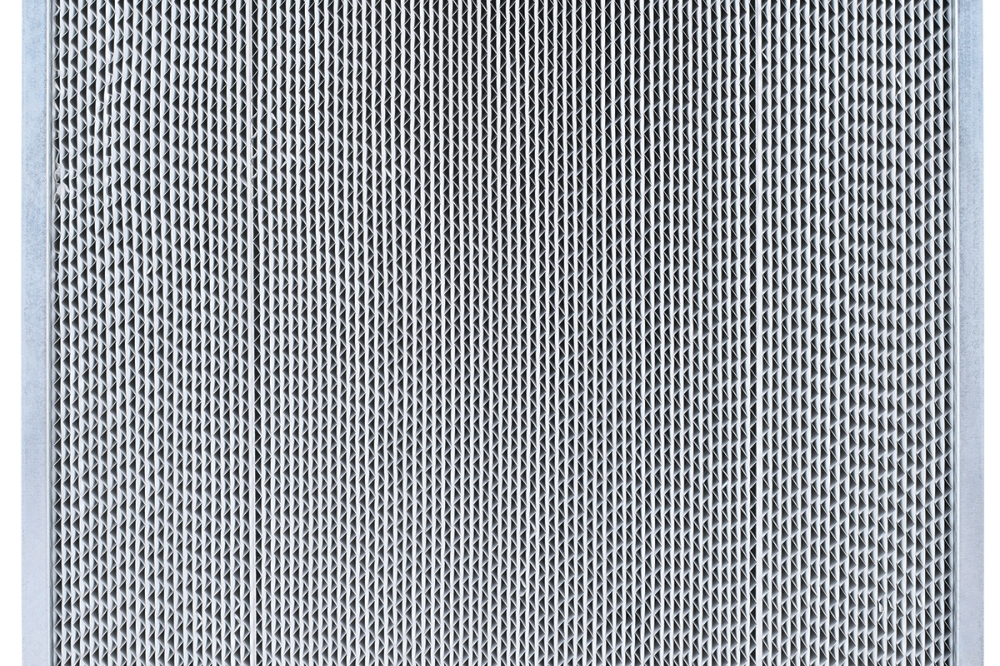

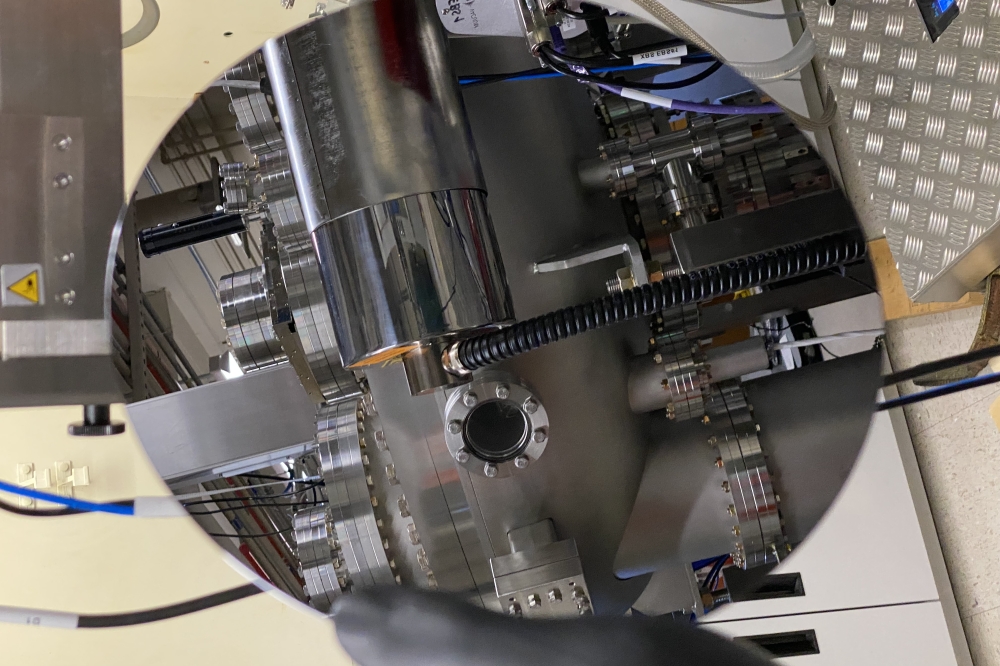

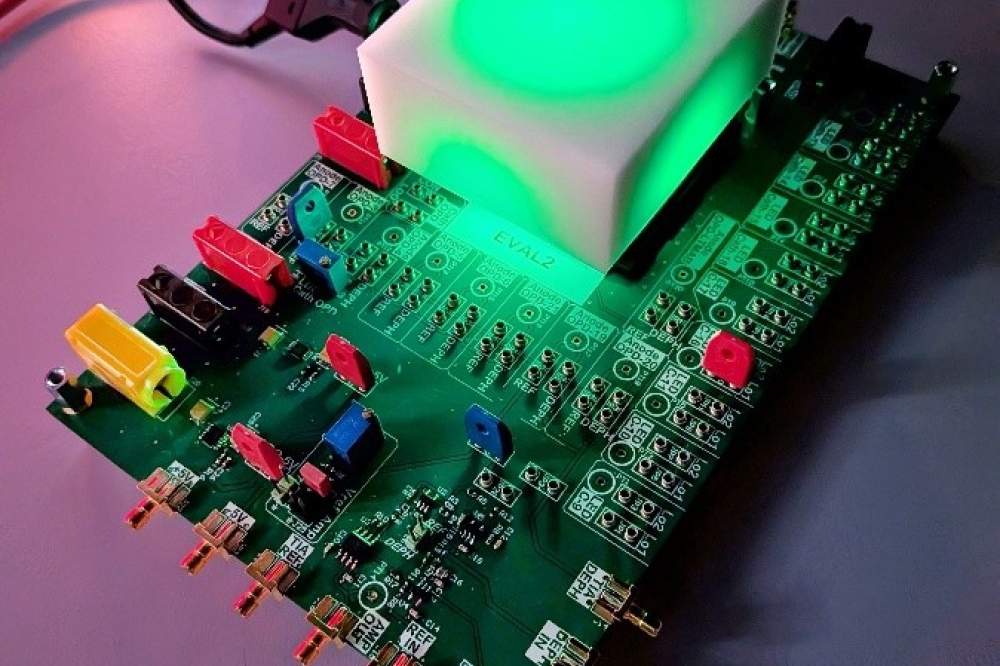

ZEISS Semiconductor Manufacturing Technology (SMT) continues to deploying its new AIMS® EUV 3.0 systems globally at major semiconductor manufacturers. This new generation sets a benchmark in photomask qualification, crucial for performance and functionality of next-generation chips.

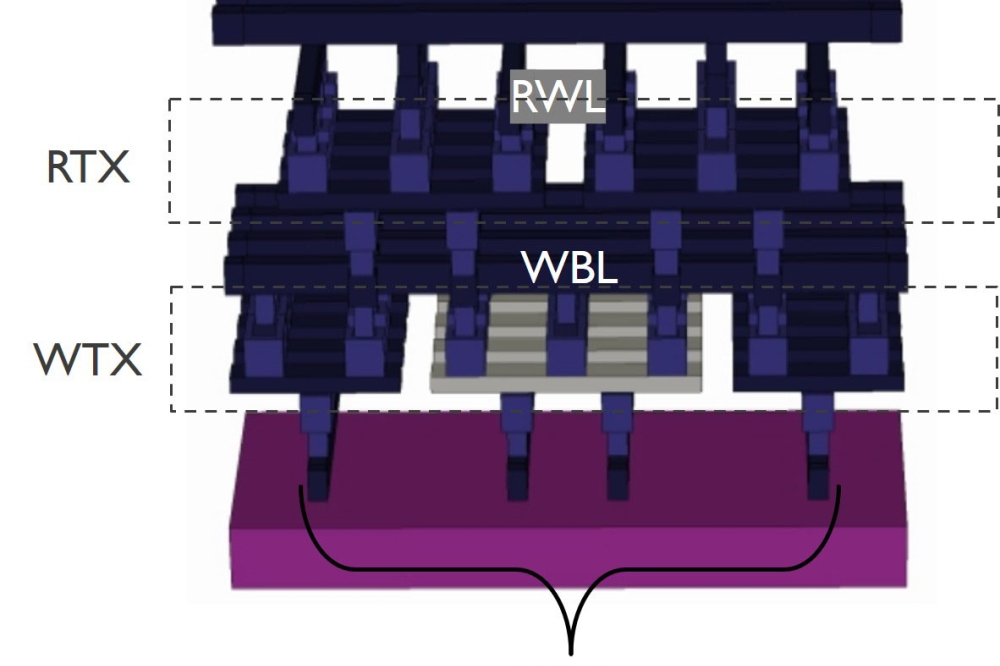

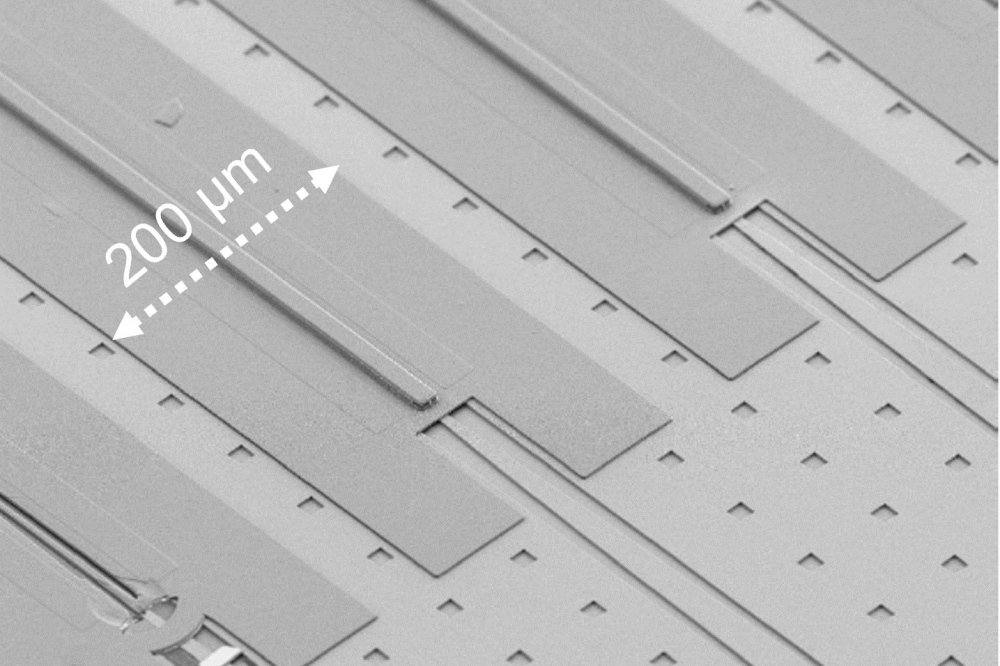

A key feature of the AIMS® EUV 3.0 is its improved scanner matching. Thanks to Digital FlexIllu capability, the system can emulate any illumination setting, delivering reliable results on defect printability. The platform supports both Low-NA-EUV and High-NA-EUV lithography, providing future-proof flexibility for chip manufacturers to meet various needs and gain strategic advantages. Compared to its predecessor, the new generation triples mask throughput, increases productivity and offers flexible illumination for customized light settings tailored to specific mask requirements.

The new generation of production-proven actinic mask qualification systems ZEISS AIMS® EUV 3.0 serves all leading semiconductor manufacturers globally. With improved scanner matching and support for both Low-NA-EUV and High-NA-EUV lithography, it offers future-proof flexibility and sets new industry benchmarks.

New features and innovation roadmap

Highlighting the strategic vision and commitment to innovation, Dr. Clemens Neuenhahn, Head of ZEISS Semiconductor Manufacturing Solutions (SMS), states: "We focus on continuous improvement and innovation, ensuring that our customers have state-of-the-art technology available to succeed in a rapidly evolving industry."

Therefore, ZEISS SMT is rolling out additional features, including Wafer-Level-Critical-Dimension Option, to pilot customers in 2026. These enhancements provide mask manufacturers with expanded options beyond defect verification after repair, empowering them to optimize their processes even further.

ZEISS SMT also remains dedicated to minimizing downtime through ongoing software upgrades, such as the overhead time improvement upgrade, and exploring further enhancements on the roadmap. Neuenhahn underscores the value proposition of the new system: "With AIMS® EUV 3.0, we’re offering a solution that delivers technological excellence and creates value for our customers in everyday production through higher productivity, flexibility, and operational reliability."

Besides the major improvements of the AIMS® EUV 3.0, ZEISS is further enhancing the first generation of AIMS EUV, with upgrades that double throughput, demonstrating its commitment to advancing existing systems and providing increased value to customers.