Yongjiang Laboratory orders Reactive Ion Beam Trimming equipment from scia Systems

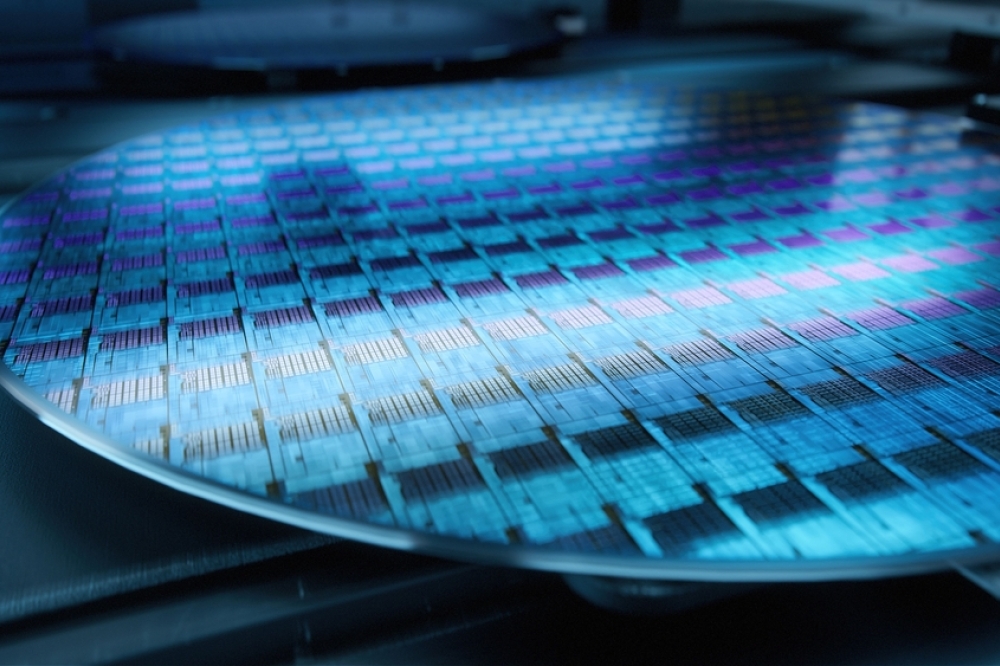

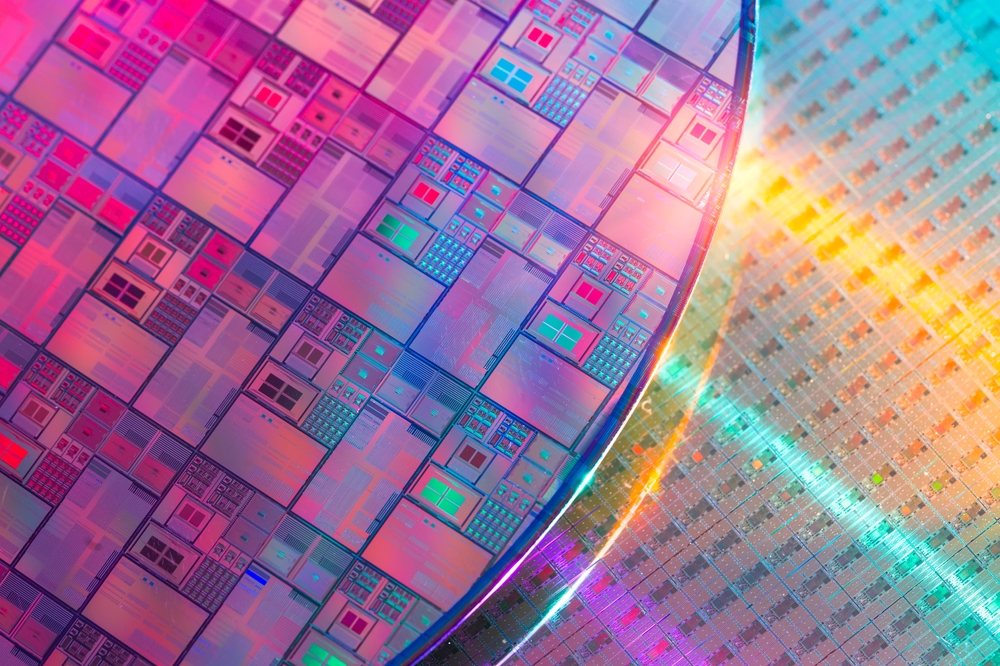

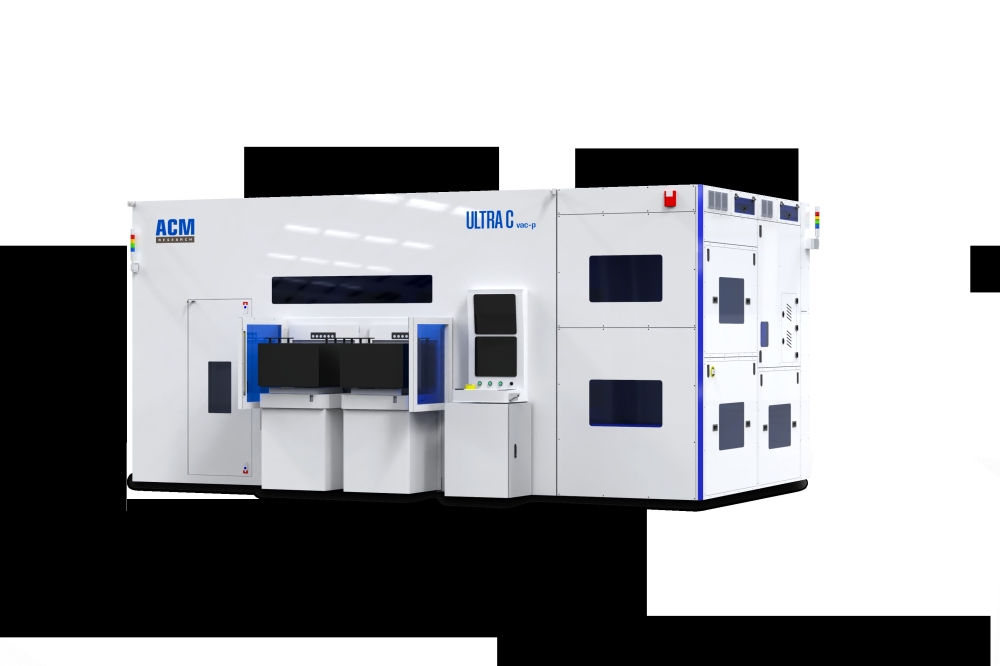

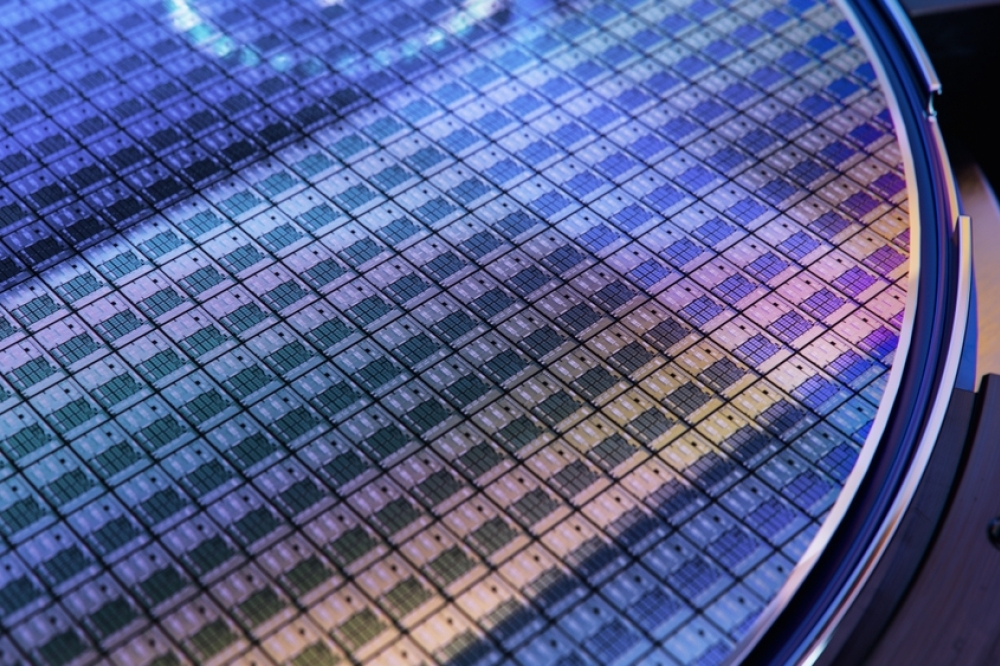

The scia Trim 200 system provides precise surface correction in film and wafer materials using ion beam trimming. The film thickness uniformity can be adjusted up to 0.1 nm.

Yongjiang Laboratory (Y-LAB), a non-profit research and innovation center, established in 2021 in Zhejiang province, China, has purchased a scia Trim 200 system.

High-Precision Surface Correction with scia Trim 200

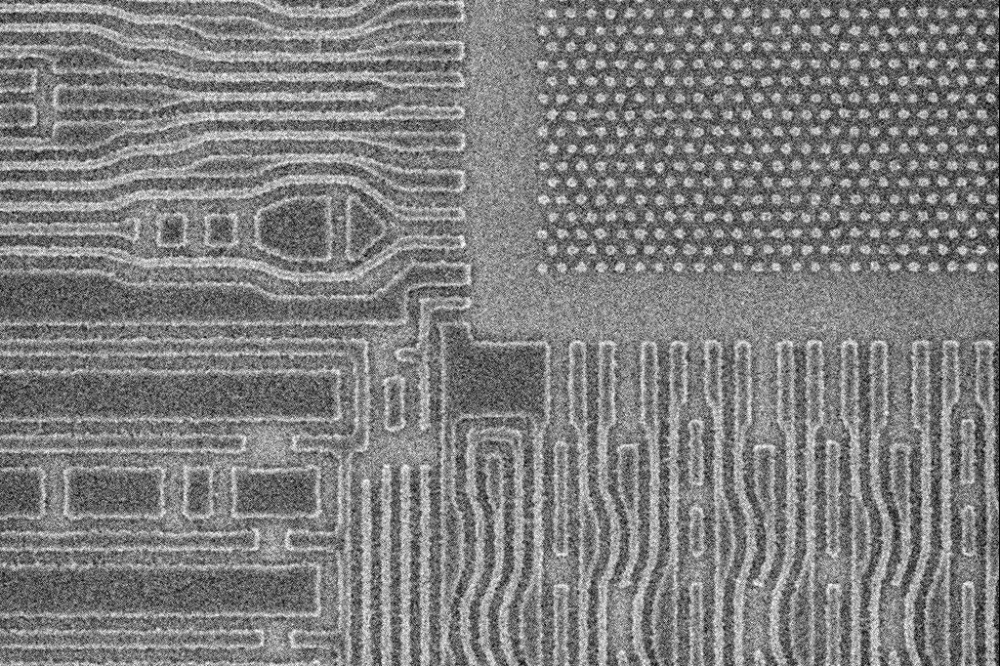

The scia Trim 200 guarantees high-precision film thickness trimming in wafer processing. Typical applications are frequency and thickness trimming in the manufacturing of acoustic-electrical devices and filters like bulk (BAW) or surface acoustic wave (SAW) filters, localized pole trimming of thin film head (TFH) applications, and dimensional correction of MEMS structures.

Designed for high-volume production and R&D applications, the system is equipped with a standard semiconductor cassette handling robot that accommodates wafers up to 200 mm in diameter.

The film trimming is performed by a focused broad ion beam with a sufficiently small focal point. The ion beam is directed to the substrate surface, causing a physical sputtering effect to remove material. During trimming, the wafer gets moved in front of the ion source by an x-/y-stage.

A metrology system detects the exact frequency topography map of each wafer area and converts this topography map into a coating thickness map. Based on that, the thickness of the coating that needs to be trimmed is calculated. Afterward, the internal control software of scia System calculates the corresponding dwell time map and follows the velocity scan profiles for the trimming process. By adjusting the local dwell time of the ion beam at specific positions, the system can control the local removal and etch non-uniformities, resulting in an impressive homogeneous film.

While ion beam trimming is done with noble gases like Argon, reactive gases can also be used for complex device structures to increase selectivity (reactive ion beam trimming, RIBT).

“We are proud that Y-Lab has opted for ion beam equipment provided by scia Systems for its laboratory. The scia Trim 200 offers a high degree of variability and is a good basis for future-oriented innovations and applied research thanks to its maximum flexibility in processing wafer materials without any restrictions and its ability to adjust the film thickness uniformity down to the atom level of 0.1 nm.” stated Dr. Michael Zeuner, CEO of scia Systems.