DuPont reshapes IC materials manufacturing for post-COVID success

Leading electronic materials manufacturer DuPont is making strides towards improving overall operational functions, leveraging the lessons learned during and after the COVID-19 pandemic. While challenges remain, the company sees many opportunities as semiconductor manufacturing enters its next phase. Demand for ICs soared during and immediately after the pandemic, but the fragile recovery points to the need for continuing innovation to achieve success in 2023 and beyond.

Silicon Semiconductor Technical Editor Mark Andrews spoke with DuPont’s Sang Ho Kang, VP and General Manager, Semiconductor Technologies, DuPont Electronics & Industrial.

Leading electronic materials manufacturer DuPont is making strides towards improving overall operational functions, leveraging the lessons learned during and after the COVID-19 pandemic. While challenges remain, the company sees many opportunities as semiconductor manufacturing enters its next phase. Demand for ICs soared during and immediately after the pandemic, but the fragile recovery points to the need for continuing innovation to achieve success in 2023 and beyond Unprecedented demand for semiconductors of all types created massive opportunities and headaches for IC makers across global markets from 2020 through the early part of 2022. Even as device and equipment sales soared, so did backlogs and a scramble to meet customer demands while maintaining quality and profitability.

Major suppliers, vendors and manufacturers were at the center of the drive to produce more chips; they also played a central role as countries such as the United States and regional economic blocks including the European Union began efforts to ‘on-shore’ IC production that had shifted largely to Asian manufacturing centers over the past three decades. Silicon Semiconductor Technical Editor Mark Andrews spoke with DuPont’s Sang Ho Kang, VP and General Manager, Semiconductor Technologies, DuPont Electronics & Industrial in an effort to delve into issues major electronic materials suppliers are addressing and opportunities that companies like DuPont see in the New Year and the years that follow.

MA: One of many COVID-19 impacts on manufacturing could be traced back to supply chain issues. Has the ‘mess’ of 2020-2021 been untangled? What lies ahead for DuPont and other major suppliers?

SHK: I think we all recognize that there are no cure-alls or miraculous solutions that can resolve all the disruptions, especially in the short term. Like others, we’ve experienced many, including raw material supply constraints and delays driven by increased demand and pandemic-related production slowdowns, as well as the scarcity of logistics resources, ranging from appropriate transport to packaging materials. I think it is particularly challenging for our industry because there are so many complexities related to quality and consistency. For example, another industry might quickly be able to change packaging materials without impact to their product, but in semiconductor materials, even changing the size of packaging could warrant rigorous testing and qualification! Likewise, we deal with a lot of temperature-controlled transport, which limits the alternatives available.

Our DuPont team has been creative and customer-oriented in navigating these challenges, with two key areas of focus. The first is enhanced engagement with logistics providers. We’re now connecting much more frequently to monitor conditions and evaluate alternatives when appropriate. Through this collaboration, we can often secure priority and advance bookings, and identify additional ports and airports that can be used when needed.

The second is enhanced collaboration with key raw material suppliers to procure materials and supplies in time. We’ve been establishing and building relationships with strategic suppliers and providing them strong visibility into our future needs. In some cases, we are collaborating with suppliers and customers to secure alternative products or sourcing locations. The past couple of years have put business continuity plans to the test, as we put some of these strategies into practice and take the learnings into planning for future potential disruptions.

We’re also continuing to invest in our regional/local capabilities by having teams close to our customers. This can help to minimize potential issues through shorter logistics lead-time between a source location and destination, and quicker technical engagement or issue resolution. As we build closer networks with customers, suppliers and logistics providers, we are striving to do this in a persistent manner with a long-term view – these cannot be sustained if acting in a myopic view or in response to a single concern. As we look ahead, suppliers won’t be fully protected from any impacts of the next pandemic or substantial disruption event, but we will be in a better position through the increased collaboration and communication across the supply chain

MA: What is felt still needs to be done to handle immediate and short-term issues while planning for a more efficient future?

SHK: When COVID-19 was identified as a global pandemic and people realized the potential risks, panic buying occurred across the semiconductor industry, much like it did for consumers. Panic buying made the industry a bit chaotic because all resources have limits, be it volume/manufacturing capacity, logistics bandwidth or labor. This created inefficiency to use these limited resources, and consequently, many parts of the industry were negatively impacted.

Continuous improvement is a big part of DuPont culture, so accordingly, there are yet some opportunities to improve internal processes for increased visibility and enhance our escalation procedures. We also have significant untapped potential in digital technology, such as by better leveraging internal data and AI/machine learning to predict and react more swiftly to future events.

I’m extremely proud of what our DuPont team achieved and learned through these challenges. Our team coordinated well and will continue to focus on enhancing closer and transparent communication with all stakeholders across our supply chain to resolve imbalances of supply and demand.

MA: What can be done to make it easier for Fabs to expand?

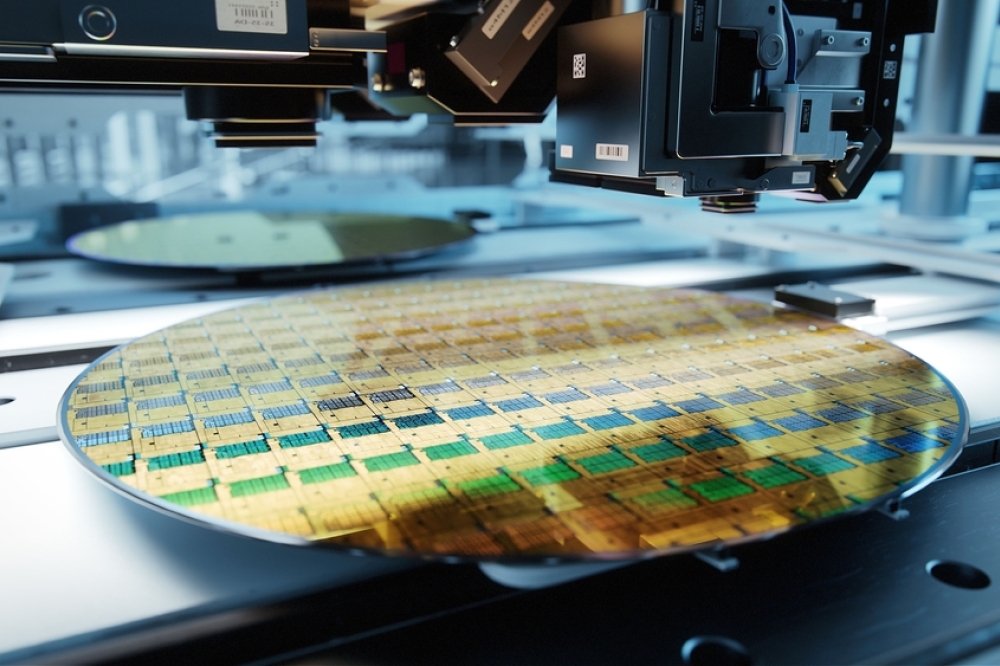

SHK: An advanced node Fab now costs $17 billion+ (USD) to build and they gradually ramp up capacity based on technology readiness and market demand. It is not uncommon to fully operate a mega Fab through multiple ramp-up phases. Like IC fabricators, DuPont, as a material supplier, follows a similar strategy for our own capital projects when expanding capacity. Our scale of investment is not the same as building a Fab, but what we’re doing is thinking about growth when expanding and building long-term asset strategies. It means we might be able to increase our footprint bigger than we need for a single project, with flexibility to expand into the future. In other cases, it means manufacturing assets that can be used for multiple products depending on demand.

The catch-up in the global supply chain will likely help to reduce lead times back to normal levels. There are no shortcuts in quality controls, testing and process qualifications, so many of these timelines will stay. However, there may be opportunities to speed up steps in other areas, such as through workforce development, so Fabs can hire the talent they need locally and quickly integrate them into their teams and work processes.

IC fabrication includes thousands of process steps, thereby very complex development phases, and device feature dimensions have shrunk to atomic levels. Often the bottleneck in capacity can be driven by the pace of process innovation to deliver acceptable device yields. Therefore, strong collaboration across the value chain and open innovation can help speed up cycles of learning. DuPont works very closely with our customers to develop new material technologies and scale up to meet the customer and industry timing. We stay in sync so that new materials are available when our customers are ready for them.

MA: Are there new ideas around how to make a Fab more agile and productive while still maintaining profitability?

SHK: Today, improving productivity in semiconductor fabrication can be done by engaging in yield and throughput optimization between tools, materials and process modules. Improvements in any of these areas or their interactions can help free up capacity. DuPont is already working across the value chain to create value for customers.

MA: Bringing skilled workers into semiconductor manufacturing was a challenge even before demand soared. How can the semiconductor industry attract and retain more talent?

SHK: With more growth ahead, there will be many new roles to fill in the coming years. One of the things our industry can do to attract talent is to share our story with new audiences. Today, a lot of technology companies are more effective at sharing a vision that is compelling to job seekers. For example, I’ve hosted visitors at DuPont sites who were completely surprised to learn about the sophistication of semiconductor materials and important role they play in enabling technology.

We also have an opportunity to communicate the wide impact of the semiconductor industry. More and more, people want to know that their work will have a tangible impact on daily life, and we find this to be especially true with the younger generations in the workforce. Organizations need to find ways to communicate the extraordinary value semiconductors bring to society, enabling things like 5G, IoT, autonomous and electric vehicles, infrastructure, data processing and consumer electronics. People will personally identify with different applications, but because these technologies encompass so many areas, many people should be able to connect a meaningful purpose to careers in semiconductor.

Retaining good talent is about investing in people. It is critically important for people to know they are valued, and to continue to have opportunities to grow and develop throughout their careers. At DuPont, we try to offer learning opportunities in both technical competencies and soft skills, within the company and through external programs. With such a large and diverse organization, employees can also develop new skillsets and experience in a new role within the same company. We’ve seen talent move between DuPont businesses, between functional areas, and even between geographies. While depth of technical expertise is essential for certain roles, these types of moves can also make our organization stronger and more agile.

Another important factor is engaging people. It’s important for people to understand what they are working on, align their own goals to business goals, and connect how those goals advance the organization’s strategy. We can communicate within our organizations to recognize teams for their achievements, embrace innovative ideas, and build a strong culture around people. At each DuPont Electronics & Industrial site, we recently launched culture teams that are led by employees. These teams organize events to build connections and share important insights with leaders. I am one of the regional sponsors for our culture teams, and we often meet over videoconference to share successes and best practices. It is extremely encouraging to see how these employee-organized initiatives are making a difference in engaging people and making each location a great place to work.

MA: How can the industry attract and retain more talent amongst groups that have typically not gone into engineering as a profession or become Fab technicians or service personnel, such as women and underrepresented minority groups?

SHK: To attract and retain talent from underrepresented groups, organizations need to be intentional with strategic diversity, equity and inclusion (DE&I) plans and follow through.

One place to start is by examining unconscious or implicit bias that might exist in recruiting processes. For example, are there biases in the way a job description is written? There is also an option to seek out underrepresented groups, such as by collaborating with universities or community groups to increase reach.

Next, we need to look at whether our organizational culture is inclusive for these groups, and whether there might be factors influencing the current organizational makeup. Employee affinity groups can be a great resource for uncovering gaps and helping teams to address these factors.

MA: How can a multi-national company with very diverse employee populations help individuals with very different cultures and senses of personal responsibility to all work together harmoniously?

SHK: One of DuPont’s core values is respect for people. This means treating employees and partners with professionalism, dignity and respect, fostering an environment where people can contribute, innovate and excel. Leaders must have zero tolerance towards behavior that is disrespectful.

There are many tangible actions possible to implement this value. For example, we start by embedding our core values into new employee orientation and educating people on how to recognize unconscious biases.

At DuPont, we have employee resource groups that help the organization respect and embrace differences, such as the DuPont Women’s Network or DuPont Early Career Network. Groups are operated locally at our sites with connecting points across the broader organizations, and senior leaders take an active role in sponsoring these teams. These affinity groups have elevated many insightful learnings and led to changes within the company. We also have DE&I champions throughout our organization who help to coordinate efforts and advocate for these principles.

MA: How can companies help create a more harmonious workplace that is also highly productive and therefore, more profitable?

SHK: It is important to be aligned around a strategy and purpose. By nature, we are social creatures, so having common goals helps to connect everyone with a common thread. Organizations must have a very clear strategy and should be willing to communicate it with their teams. A collaborative and aligned workplace starts with leadership, so leaders need to adopt a people-centric and inclusive mindset. Leaders can demonstrate transparency and encourage interaction between teams.

DuPont’s Sang Ho Kang