Customer collaboration crucial for productive change

Mark Andrews, Technical Editor of Silicon Semiconductor magazine, speaks

with ALEX SMITH, VICE PRESIDENT MARKETING AND OPERATIONS AT EDWARDS

VACUUM. The conversation covers Alex’s leading role in focusing on the

company’s sustainability, performance enhancement and optimisation

objectives, all of which contribute towards the semiconductor

manufacturing industry’s growing circular economy momentum.

MA: IC manufacturers, semiconductor manufacturers, were challenged like never before during the pandemic. We are now in the COVID-19 recovery phase, but we’re still dealing with reverberations across the supply chain. Could you please describe the challenges and needs that Edwards Vacuum sees most often with their customers operations these days? In other words, what do they need help doing, are they struggling with certain things?

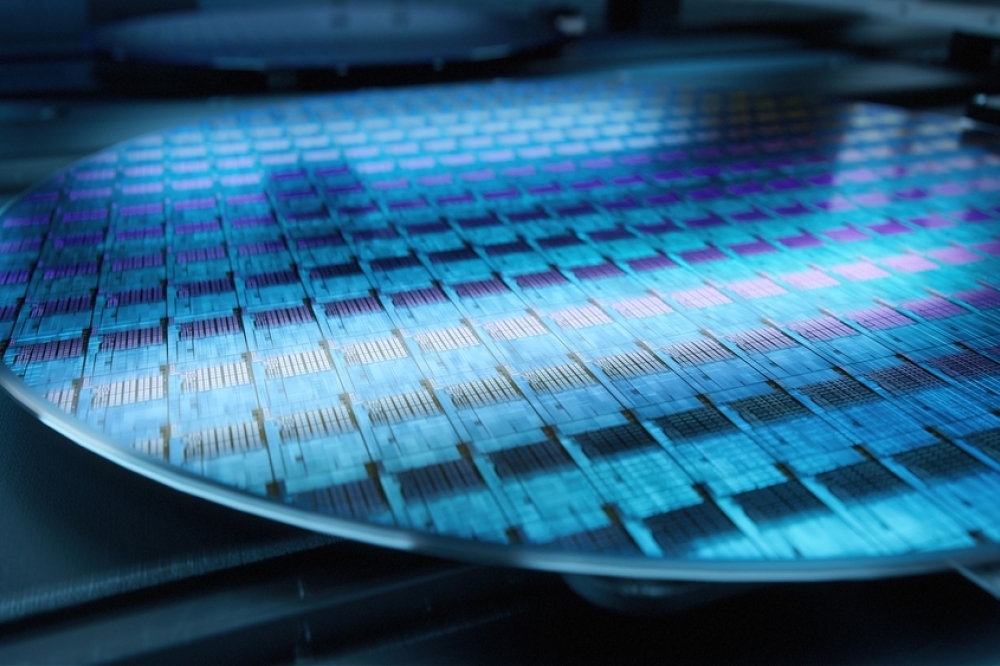

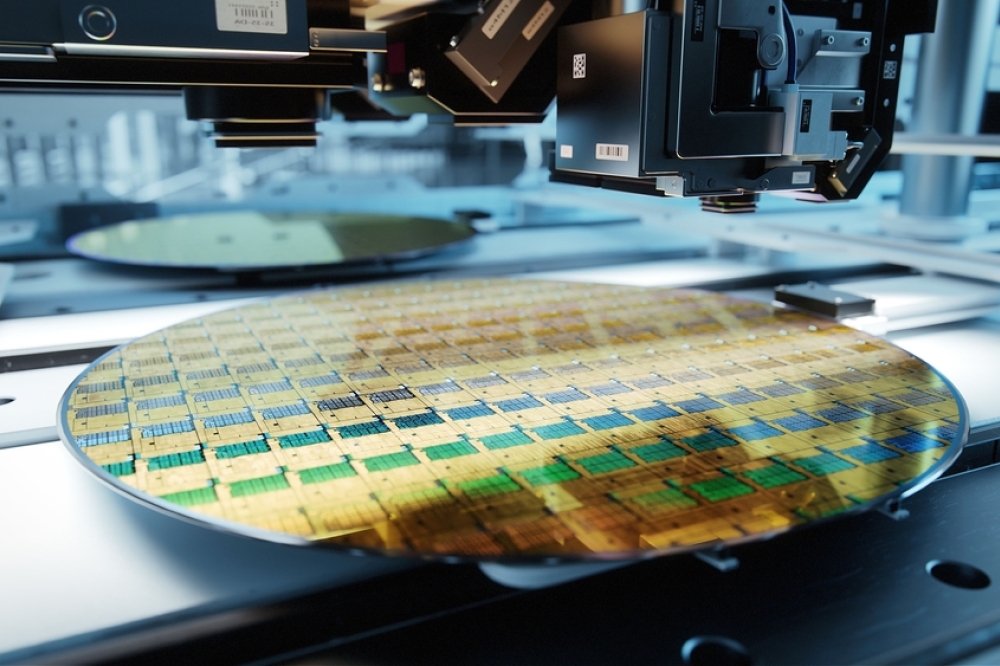

AS: The biggest challenge in our industry is the demand for more chips, and all the predictions see that continuing. It’s a good problem to have. The semiconductor shortage has also been helpful – I think everybody now understands what we do for a living. But it really faces a lot of challenges. Making chips, especially the advanced ones, is not easy, it’s technical, it’s difficult. The manufacturing process comprises a complex, widely distributed supply chain. So, it’s going to take time, and it’s going to take money, and it’s difficult just to expand capacity. We’ve also got a long history of ups and downs within the industry.

These were levelling out a little bit just before COVID. But then when COVID hit, it really showed the vulnerabilities in our supply chain, and these are now being compounded by other things like geopolitical developments, cost challenges - pure volatility. It’s just completely unpredictable at the moment, and we need to get back to stability.

And there’s now another layer to this challenge. There’s a growing awareness of the urgent need to see what we can do to combat climate change. Compared to some industries, ours is not a huge direct emitter of greenhouse gases, what we call scope one emissions. But we are a large consumer of power, both in our manufacturing processes and in the use of our products by our customers. This makes our scope two and our scope three emissions quite large. And then, beyond these practical reasons, we’ve all got to live in the world we’re helping to create. We have ethical and moral obligations.

Many of the challenges our customers face are not really tied to recent events like COVID, geopolitical events, or the climate change that we’ve already discussed. They’ve been around for as long as the industry has existed and include constant pressures to minimise planned and unplanned downtime, to maximise tool availability, and to get more for less from the supply chain, all at the lowest environmental costs. In the past, it’s been, I think, quite easy to overlook the critical systems we have in the fab that enable the process – things like vacuum pumps and abatement systems. But trust me, this is really changing. Customers are really coming to appreciate the significant role that these systems now play in optimising and reducing the environmental impacts.

MA: It is amazing, isn’t it? I like to think of it as out of sight, out of mind. When you go on the production floor, you have no idea, unless you know how a plant is laid out, that almost every tool you see on that floor has a vacuum and abatement system, in most cases, underneath it, in the subfab. Well, what do you see as the best way to resolve customer issues and close that gap, if you will, between where they are and where they need to be according to whatever measure that you think is relevant?

AS: Of course, the only measures that really matter are the customers’ measures. We often refer to those as fab metrics. We collaborate very closely with our customers to understand their issues and their challenges. And that really is the fundamental first step to resolution. We get to understand what the challenges and the problems are. If we use fab metrics as our ultimate measures as well, then it means we’re really aligned with our customers problem statements. So that in turn means we’re always working on solutions to their problems. And that’s really important. We absolutely must be solving their problems.

To give a more direct answer, fundamentally, fab metrics measure performance in key areas like safety, quality, delivery cost, people, and environment. Semiconductor manufacturing is arguably the most complex and demanding industrial process ever developed. And although the process is pretty much the same everywhere at the highest level, it really is remarkable the differences that we see among manufacturer when you get into the details – new tools, new processes, every new material brings specific challenges. But we can always align with our customers’ challenge through these high-level fab metrics.

And that’s the key. We can always make a tangible link through those fab metrics. Our products sit at the outlet of most process tools where we’re tasked to extract process gases and by-products and render them safe for release or disposal. It’s only by collaborating with our customers that we build the trust needed for them to share and collaborate in addressing their specific challenges. The more closely we can work with them, the more they’ll really appreciate the value that they can derive from our domain expertise in all these areas.

MA: Today’s semiconductor manufacturing environment is more dynamic than ever, as you have just mentioned. They deal with these incredible necessities, like constant product evolution. People outside the industry don’t necessarily realise that they’re constantly pushing new designs through. The way I like to think of it is that, just when we get the recipe just right for this generation of device, we’re moving on to the next. You’re redoing it. What can semiconductor manufacturer really achieve? We hear the term circular economy a lot in this regard. Should that be the goal, or do you think it’s more about sustainability?

AS: I think sustainability is the goal and circular economy is one of the ways to achieve that goal. An environmentally sustainable manufacturing process is one that really achieves the immediate goal, manufacturing a product without damaging the environment. In terms of the value created in the product, a circular model is a way to approach sustainability by thinking about potential to reuse, remake, and recycle the product or its components at every point in their life cycle. So, yes, circular economy and sustainability can and should be pursued simultaneously.

MA: Do you think now really is the right time to embrace change? Because some people would argue that we’re dealing with so much right now, we just want to get back to normal and then we’ll talk about the future. But is that really proactive?

AS: Yes, I think the time really is now. It’s become really apparent, I think, that if we don’t take any action, there will be some pretty disastrous effects. So, by any calculation, the cost of ignoring climate change far outweighs the cost of taking action to stop or even reverse it where we can. And I think the longer we wait, really, the higher the cost of the inaction. I think that’s where I’m at with it. I think, we have got to act now, and we must move quickly.

MA: I think, and I certainly agree, about the impacts of climate change. For those of you who don’t know, I’m based in central Florida. And right now, as this interview is taking place, hurricane Ian is bearing down on us. Now, for those of you who aren’t familiar with tropical cyclones, they don’t usually grow rapidly in intensity the way this one has. It went from a minor storm to a killer storm in the span of 24 hours, and everyone is attributing this to the fact that the waters are hotter than ever before. And that’s what fuels any kind of a tropical cyclone. You may not live in Florida, but trust me, when that storm hits, or the next time your forest catches on fire, or whatever it is that matters the most for you, you will see the impact. Do you think this will change how the product is conceived, some of the core processes? Or is it more about working hardware and the way that we use our hardware to make it more efficient?

AS: I think it’s both. I think there are definitely gains we could make in the hardware, and we do that. I think that’s one thing that the organisation really strives to see. How can we create products that are more efficient than any of their predecessors? And that’s important because we can then show that pursuing circular economy and sustainability drive does not really add cost. Actually, we can often help to reduce cost, that’s really the benefit. Right, so energy is expensive, power is expensive, and it’s not likely to become any less expensive, certainly not in the foreseeable features. Reducing that power consumption, reducing the operating cost, really is going to go straight to the bottom line. While improving profitability it also reduces the scope two emissions – greenhouse gases that are generated by power suppliers. Clearly one huge step forward for our industry and for everyone would be if we could move to renewable energy sources. That’s something everybody in the industry and in the world needs to collaborate to achieve.

MA: When you look at the advances being made by some of the major retailers, for example Amazon, they’re converting all of their warehouse operations to green energy over time. And considering how big that company is, it’s going to have a definite impact. Do we think then that sustainability can be part of an incremental program. Must you take baby steps at first or is it better to jump in with both feet?

AS: I think it’s tough, and it depends a little bit on where you’re starting from. The important thing is everybody gets on board, and you have got to work out the pace at which you want to go. But it requires a shift, a massive shift. Moving to circular models and circular design, you have got to start with modular design and then you’ve got to see how it fits in with a circular economy model. So how do you move from the old make, use, dispose approach to the new make, use, reuse, remake, and recycle model? It’s a new attitude, it’s a new mindset. And really, manufacturers and industrial organisations must embed this in their business models. That’s a really key element, and I’m an optimist here. I look at the progress we as a society have made, what progress businesses have made in the last decade, since we started to take climate change a lot more seriously. Now we can look around and read about things on a daily basis where we see either new initiatives or innovative technology that we think can really make a difference.

As an added benefit, most of these innovations can and will offer real commercial opportunities. Here at Edwards, we’ve tried to find the opportunity everywhere that we look with these new innovations. How can we build on what we’ve been doing for many years? For us, our circular economy journey started years ago, even decades ago. Our service teams, for example, have been remanufacturing our products for decades. And this was our proven circular service business model. With this model, we keep most product life cycles well above ten years. Then we have product upgrades that extend the use and the reuse opportunities, and that can extend the performance capabilities of our products within existing fleets. That’s the interesting part. It comes to your question of how do you start? You start quick, you start slow, I think it depends on where you are in your journey. And we were lucky that we had a good foundation of circular principles already. Many of the developments we’ve had in more recent years have been around smart manufacturing and digital advances. Through advanced data analytics and machine learning, we can now predict machine performance, lifetime, and maintenance requirements.

Not only has this helped eliminate unplanned downtime and productivity risk, but it enables the creation of new sustainability business models, and that provides and enables clear environmental improvements. Our business models need to be underpinned by results, and they need to focus on the customers’ needs, not just our capability. Objectives like eliminating product loss, improving tool uptime, reducing unpredictability, preventing disruptions to operations, all of these things are really critical. But now we can also tie in lower costs for energy and consumables, machine optimization, and less waste. These new models allow us to be true partners and to co-manage our customers’ risk.

MA: You’ve mentioned a couple of times now about working in close partnership with your customers. I understand, coming from the industry, that semiconductor manufacturers can be rather hesitant to share details about their operations, even with trusted vendors with whom they’ve had successful relationships for many years. Is that a major issue to overcome - that idea of trust and collaboration and working closely and openly with your major vendors?

AS: Yes. We approach this by starting small. We develop and test small scale solutions in collaboration with our customers and focus on solving a specific problem. This allows us to learn what resonates with the customer. We know customers are sensitive about their information and sensitive about their data, but when we can build trust and demonstrate tangible value from sharing data we have found a lot of success. When they see real benefits –reduced cost of ownership or reduced risk – from sharing data and information and collaborating with us, trust and openness grow naturally. As a result, we’re starting to have success. In the last two years we’ve really started to scale these models and solutions in various fabs at very different lifecycle stages to solve a multitude of different problems. And it’s all progressed rather rapidly into a comprehensive program.

It requires a holistic approach, definitely collaborative and definitely solving customer problems, but where we can effectively integrate technology, process, and people using the principles of circular economy, we’ve really got a proven solution, ready to deploy.

MA: It sounds as if someone who realises this need and realises the opportunity, especially if they’ve been pressed by their facilities management about cutting down their electrical costs or other issues, needs to act. Whether their motivation is altruistic or really bottom line driven, they should talk to you about getting started - if they aren’t already engaged in some kind of a program to make their systems more responsive and more efficient? That’s a good way to begin, to give Edwards a call?!

AS: Absolutely. We really are engaging with all of our customers, and we want them to join the journey with us. We want them to be collaborating with us, we want to co-manage their risk. And we want to be their partners through this. And I think that we absolutely have some solutions and some examples that really show the value added. We believe the time is now for the whole industry to start collaborating.

Let’s embrace the principles of circular economy in new business models. Together we can create a sustainable and more profitable future for everybody.