Rudolph Technologies advances 3D metrology system

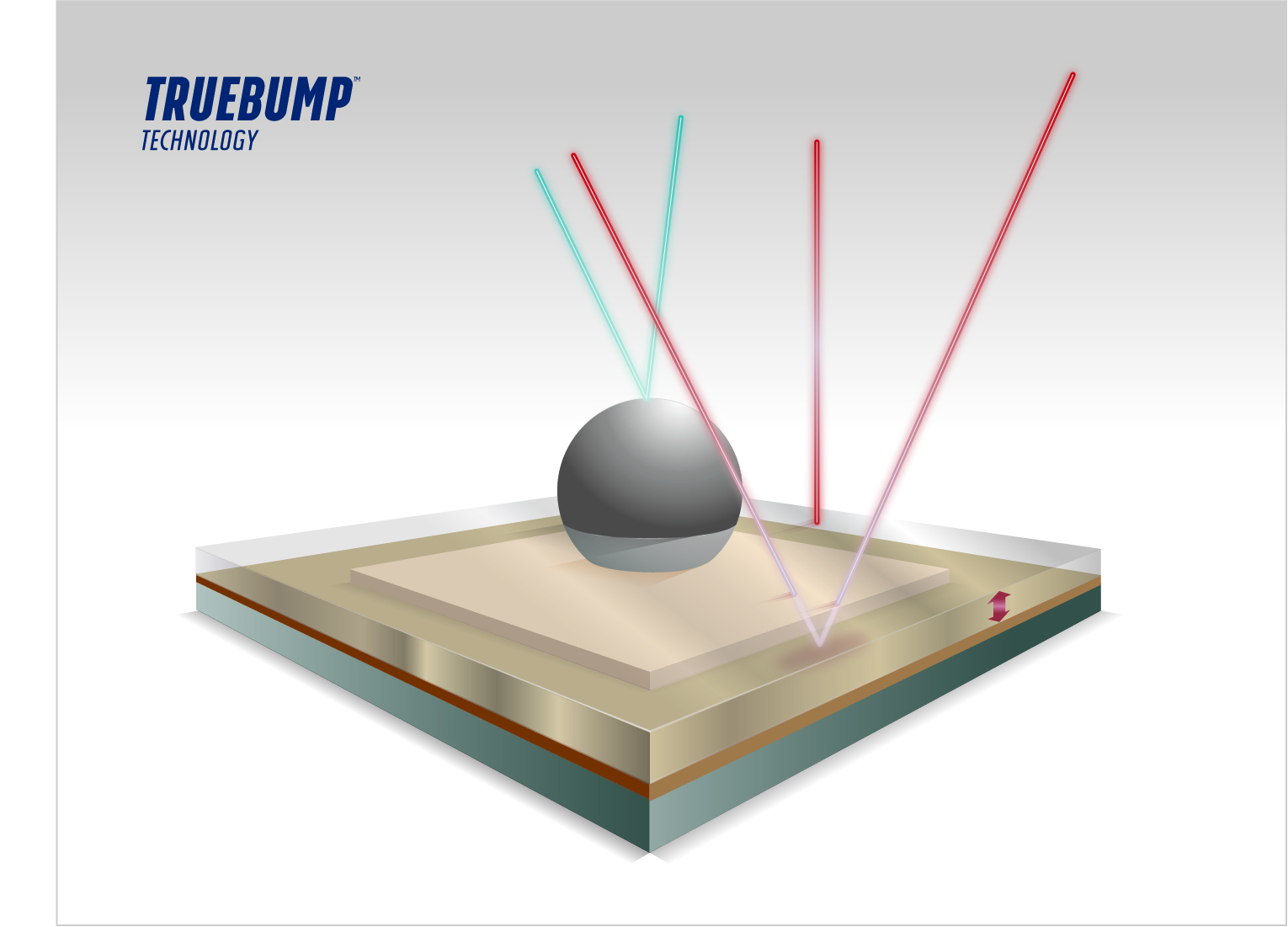

Rudolph Technologies has announced new Truebump Technology on the Dragonfly Inspection System. The company says Truebump Technology provides fast, accurate and repeatable three-dimensional (3D) metrology for all advanced packaging bumping applications, from copper (Cu) pillar, to microbumps, and even large C4 bumps.

With the Dragonfly system, the advanced packaging industry now has premier high-volume 2D inspection and 3D bump metrology on a single platform. The first Dragonfly system with Truebump Technology has shipped to a major IC manufacturer in the United States. "Truebump Technology combines multiple 3D metrology techniques to provide faster, more accurate, and more repeatable measurements of the 3D features that are critical in advanced packaging technologies," said Matt Wilson, senior director of inspection product management, Rudolph Technologies.

"As 2D and 3D dimensions decrease, the tolerances for manufacturing become tighter, and device stacking continues to drive an increase in functionality. Because these 3D connections are so vital for reliability, the bump height measurements need to be absolutely accurate." Wilson continued, "A single wafer may contain 50 million bumps, each with multiple data points, creating massive amounts of data. The Dragonfly system's integrated connection with Discover analytics software gives users tools to visualize data, correct coplanarity variations, and improve yields." Truebump Technology is three times faster and 25 percent more repeatable than Rudolph's previous generation tool.

The Dragonfly system's high volume throughput combined with industry leading accuracy and repeatability enable further adoption of stacked devices in advanced packaging applications that fuel today's drive for thinner and lighter products that deliver more capability in a smaller form factor. Visit the Rudolph booth 686 at SEMICON Taiwan to see a live demo of the Dragonfly System.