Urethane Improves precision of wire guide rollers

High-performance polyurethane can be engineered to produce more durable and consistent wire-cutting rollers to produce wafers. The manufacturing of wafers for the microelectronics and photovoltaic industries involves a multitude of critical processes. One of the first of these is the precision cutting of ingots or crystals, typically composed of hard and brittle silicon, into uniformly sized wafers that are suitable for the processing of silicon chips.

In a production environment, this cutting is typically performed by multi-wire saws composed of diamond-coated wires precisely and evenly spaced in a belt-like configuration. The cutting of the ingot or crystal of silicon material is performed in one pass, resulting in dozens or even hundreds of wafers.

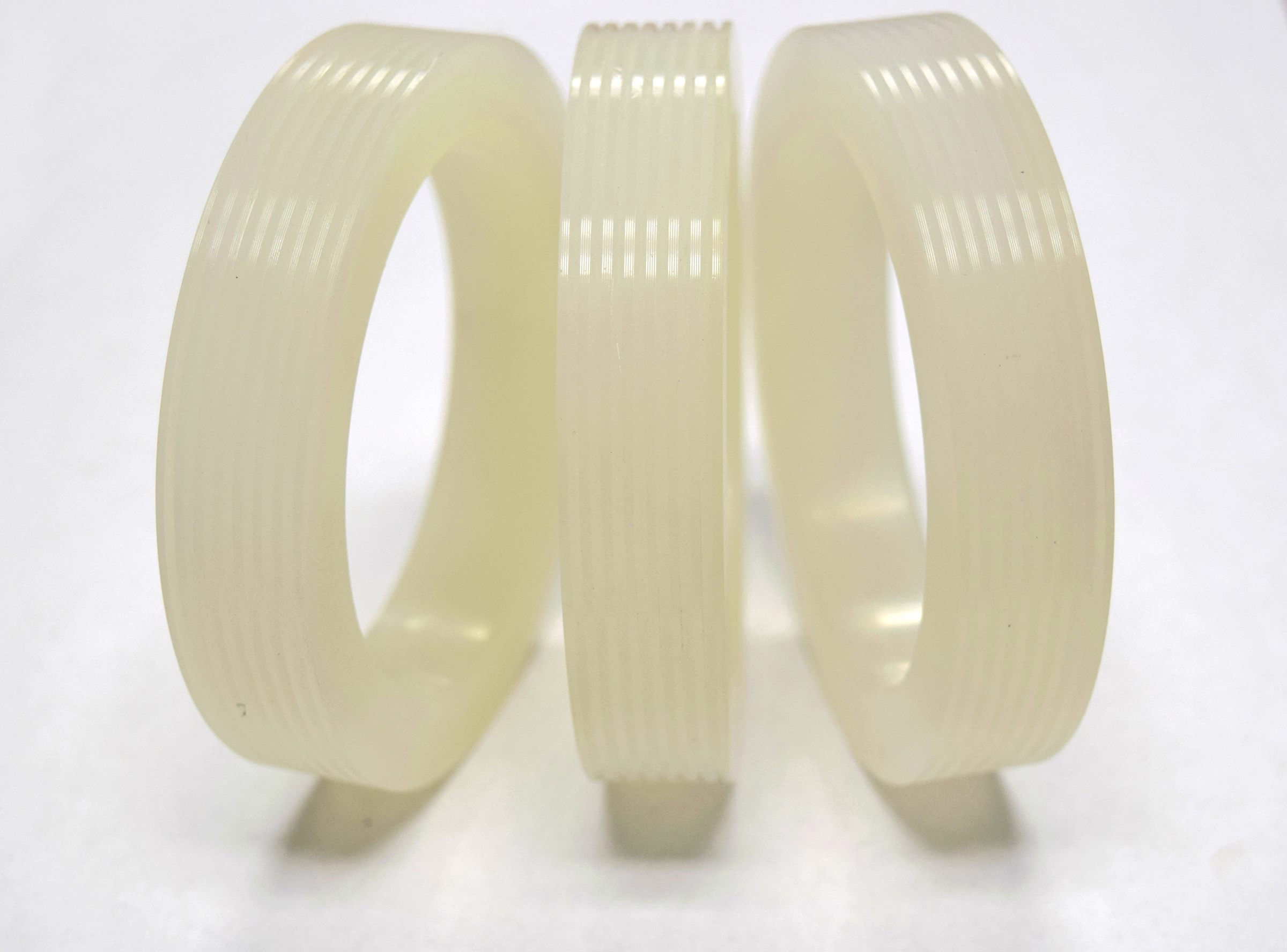

To achieve the ideal spacing between wires, as well as maintain the ideal wire tension, precisely manufactured rollers are used. This includes smaller "tensioner" rollers along with a larger roller with machined notches that keep the diamond-coated wire in place.

Because the accuracy of the wafer cutting process is dependent on the durability and consistency of the rollers, those that lack material strength or precise geometry/dimensions can fail prematurely. This can lead to costly unplanned downtime, wasted materials, and potential delays in subsequent operations.

Fortunately, high performance rollers are available that utilize unique, more durable, formulations of urethane and can be machined to meet the high tolerance requirements with consistency from part to part to ensure the ideal multi-wire cuts.

The majority of wire-cutting rollers in use today are composed of urethane (short for polyurethane). Shorter rollers, which typically cut up to 30 wafers simultaneously, are made of high-performance, cast and machined urethane. The longer rollers, which often cut up to 300 wafers, are often coated with urethane sleeves having similar properties.

"Urethane is the preferred material for both long and short wire cutting rollers," says Greg Cappaert, Technical Sales Engineer at Argonics, one of the U.S.'s largest producers of wear-resistant urethane products.

"Cast urethanes are tough, abrasion-resistant elastic materials that combine many of the performance advantages of high-tech plastics, metals and ceramics along with the resiliency and flexibility of rubber parts." Because urethane's properties can be adjusted over wide ranges of hardness, resilience, spring rate and dynamic properties, its versatility offers custom solutions to difficult design challenges.

"Urethane, even in relatively small quantity production, can be adapted and tailored to prioritize the physical properties that design engineers need," says Cappaert.

Urethane's properties are vital to high-volume production operations that utilize multi-wire saws to slice wafers as thin as 80-100 microns. Any deviation in wafer thickness or profile will bring a cutting operation to a halt and, unless spare rollers are on hand, create serious production delays.

Cappaert adds that urethane rollers used on wafer wire-cutting equipment are essentially "consumable" items. The shorter rollers, also known as tensioners or pulleys, are replaced several times a year. Longer rollers that have urethane linings must be recoated as much as 40-50 times annually. Cappaert says that much of the turnover of rollers results from rollers falling out of spec prematurely due to shortcomings in urethane formulation, casting or machining.

Because urethane is an engineered material, many problems can be overcome by adjusting formulation to meet the specific requirements of an application, as well as rigorous testing and stringent quality control of individual parts. He also notes that polyurethane rollers can be engineered to deliver extreme accuracy in both wet and dry operations, such as machined tolerances to +/- 0.004" (+/- 0.10mm).

Cappaert characterizes the production of cast urethane rollers as complex and highly sensitive. For that reason, Argonics casts, machines and inspects each individually. When larger urethane-coated rollers are approaching wear limits, these must be stripped and re-coated using the same types of stringent procedures.

Although specific customer formulations and design information are considered proprietary, Cappaert says these methodologies can lead to improvements in wafer warp, consistency of cut, and thickness variation while also increasing roller longevity.

Another difficulty that many suppliers and users of precision wire cutting equipment can relate to is supply chain issues. Depending on inventories on hand, untimely deliveries of urethane rollers "“ possibly due to premature failures "“ can shut down wafer cutting, resulting in costly delays down the rest of the production line. Cappaert recommends working with a manufacturer, like Argonics, that is willing to help solve these types of costly delays.