ClassOne cuts Via Liner Plating Costs

CopperMax chamber reduces metallisation costs by around 70 percent

ClassOne Technology, manufacturer of Solstice plating systems for ≤200mm wafers, has announced a new plating technique that provides significant cost reductions for compound semiconductor manufacturers who use gold plated vias.

"We have compound semiconductor customers that use gold for via liners who are switching to copper to save money," said Kevin Witt, president of ClassOne Technology. "When they implement the copper plating on our Solstice ECD system with the ClassOne's CopperMax chamber dramatic cost reductions are obtained "“ on the order of 70 percent lower metallisation cost compared with their previous approach."

Witt explained that the new savings result not just from replacing the bulk of the gold with copper but also from the additional copper-plating economies made possible by the unique CopperMax chamber design.

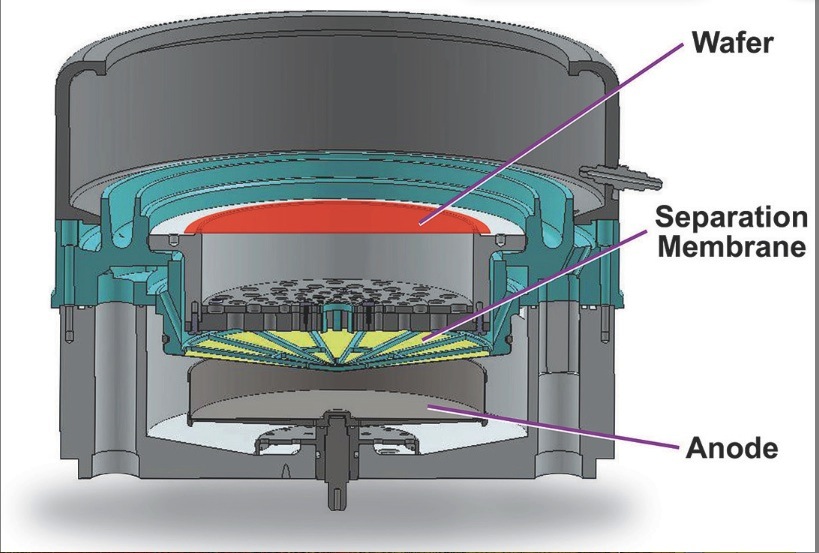

Witt noted that consumables have been the largest single cost factor in copper plating because the process required large volumes of expensive organic additives over the lifetime of the bath. But now, by employing a cation-exchange membrane to separate anolyte from catholyte, the CopperMax chamber effectively isolates additives from the anode, drastically reducing additive depletion and therefore usage. And since the CopperMax bath remains clean much longer, bath life is extended by 15 to 20 times resulting in increased uptime and throughput.

CopperMax also reduces copper anode expenses. Instead of solid machined Cu material the new chamber is able to use less expensive bulk anode pellets, cutting anode costs by over 50 percent. Plus, since the pellets provide much greater surface area the maximum plating rates can be increased.

In addition to the process improvements, the net result is a very significant reduction in cost per wafer: Compared with previous copper processes the CopperMax chamber reduces additive consumption by over 95 percent resulting in an overall cost of ownership reduction of almost 50 percent. And for users who switch from gold to copper via liners and do the plating on a Solstice system with CopperMax, the costs are cut by roughly 70 percent.