Ereztech Expands US Footprint, Opens R&D Lab

Molecular Chemist Dr. Robert Todd to Oversee New Facility Operations

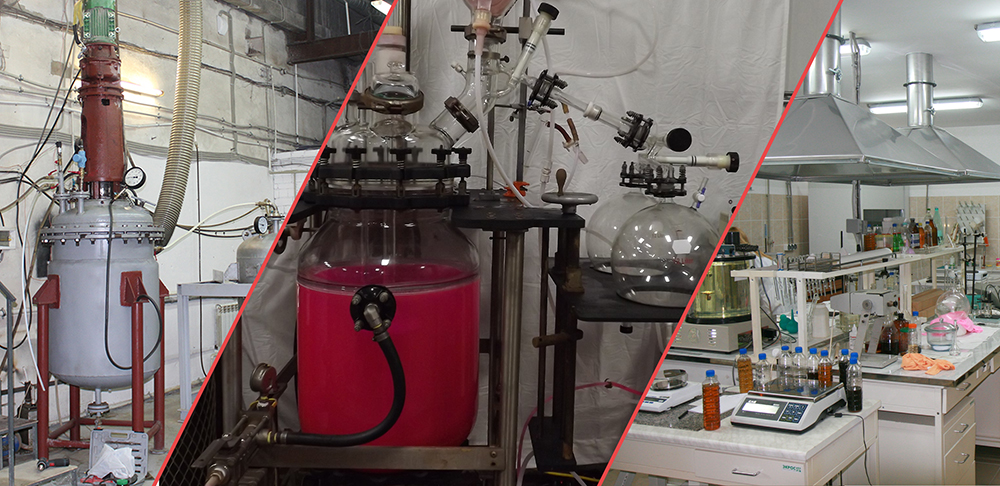

Ereztech, a provider of complete metal-organic solutions to the semiconductor industry, has opened a new research and development (R&D) lab in Sheboygan Falls, Wisconsin. The facility will augment the company’s existing European manufacturing operations by serving as a second source of products for US-based semiconductor materials suppliers and OEMs. In an interview with the company’s CEO and CTO, the executives said their expansion will enable Ereztech to extend its core synthesis and analysis expertise of air-sensitive metal-organic precursors while growing its offering of metal alkyls and hydrides, including pyrophorics. The company will also expand its portfolio of palladium, platinum and other noble metals.

Roman Rytov, Ereztech CEO, said the expansion comes at a good time for semiconductor manufacturers who have increasingly focused on atomic level deposition (ALD) or MOVCD thin film techniques for achieving enhanced device performance without investing in costly extreme ultra violet (EUV) in-house capabilities. “One of the key reasons for expanding inside the US is speed,” noted Rytov. “For some materials such as pyrophorics, the only option for transport from Europe was by sea, which added too much time in many cases. By conducting R&D and manufacturing in the US, we reduce the time to customers by weeks—at least 50 percent faster.” He added that in addition to faster delivery, the expansion helps Ereztech chemists to work in ‘real time’ with US customers, researchers and universities.

“This expansion brings our advanced and cost-efficient development capability close to our U.S.-based customers, allowing for not only a broader product selection, but accelerated compound development and greater than 50% reduction in response times,” Rytov added. “This new facility allows us to foster partnerships and intensify cooperation with our US-based customers to deliver solutions rapidly.”

Dr. Robert Todd, a well-known industry veteran, will lead the new operation. He brings more than 25 years of experience in formulation development and production to the company. At Sigma-Aldrich and ProChem International LLC, Dr. Todd led teams pursuing the synthesis of air-sensitive reagents and homogenous catalyst development for the fine chemicals, pharmaceutical and industrial markets. His expertise, combined with Ereztech’s semiconductor know-how, will allow the company to better serve its customers with a broadened application expertise to address not only leading-edge semiconductor applications but broader advanced materials and catalysis opportunities.

“My primary focus is on the development of novel homogeneous catalysts, building blocks and reagents that enable energy-efficient and economically sustainable chemical transformations of various compounds,” said Dr. Todd. “I look forward to helping our US-based customers achieve next-generation geometries with their MOCVD and ALD processes leveraging novel materials.”

As semiconductor device geometries continue to shrink, manufacturers are looking for new precursor materials to achieve finer features during deposition processes such as MOCVD and ALD. For almost 10 years, Ereztech has partnered with leading tier-one materials suppliers, OEMs, fabs and foundries on new molecule development and introduction.

Ereztech’s CTO, Dr. David Roberts, noted that the more widespread use of ALD is revolutionizing the way that advanced devices are being developed and manufactured. While the company supplies MOCVD precursors which are of vital importance to many IC fabrication processes, ALD adds a whole new dimension to the process of enhancing semiconductor performance, he noted. Even though end use products may one day be manufactured by the millions, most begin as R&D initiatives with much smaller materials requirements. Understanding and meeting customer requirements many times ‘starts small,’ but the potential is immense. Development work typically involves grams of materials, not kilograms. Roberts said that some suppliers won’t take the time to work with researchers and universities until demand is fully established, even though sizeable business can result when a development project proves successful. Because Ereztech is often involved with customers from the earliest days of investigatory work, the company can usually scale production more easily and quickly to support customers’ high volume requirements thanks to collaboration from day one.

The company’s unique approach to materials development and synthesis is embodied in Ereztech’s 25 Grams™ program for rapid new molecule introduction. Leveraging its extensive expertise in metal-organic molecules, Ereztech works in close collaboration with customers to perform custom synthesis in multiple trial runs of 25 grams each. Once a 25-gram trial passes customer testing, it is put into production of (typical) quantities from 40-100 kilograms.

Rytov noted that the new Wisconsin facility currently employs nine persons and is growing rapidly; the company has more than 50 chemists and more than 500 methods of synthesis using industry-proven, highly reliable methods designed to be scalable. The current product portfolio includes more than 800 high-purity compounds that is constantly expanding. Visit the company’s website for a complete listing of currently available materials and additional information.