IMT Modernizes MEMS Foundry Services with Plasma Etch Solution

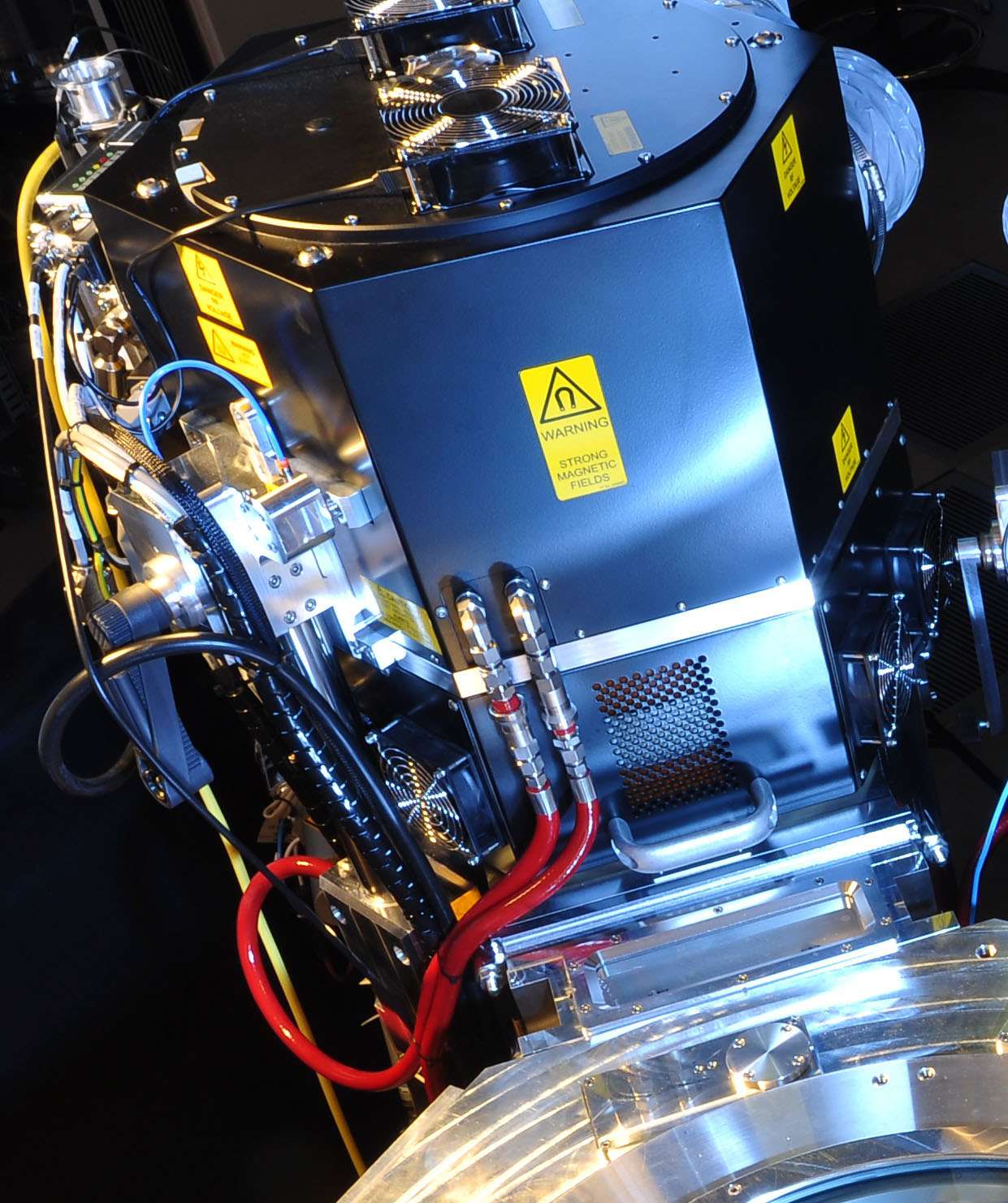

Innovative Micro Technology (IMT), a global leader in the development and production of complex microelectromechanical systems (MEMS), today announced the purchase of an Omega Rapier plasma etch system from SPTS Technologies, a KLA company. The installation of the Rapier™ this month will put IMT at the cutting edge of MEMS and sensors manufacturing and extends development and production capability for its growing customer base in photonics, BioMEMS and sensors.

“The MEMS industry is experiencing a resurgence of growth driven by a proliferation of innovative new communications, sensing, and medical applications,” stated Eric Sigler, CEO of IMT. “SPTS Technologies is at the forefront of MEMS manufacturing with its deep reactive ion etch (DRIE) solutions, having been a co-developer and first licensee of the ‘Bosch Process’. The addition of the Rapier DRIE capability allows us to offer an industry-leading technology to our foundry customers while expanding capacity for future development and new applications. This investment exemplifies our commitment to technical excellence, even in these uncertain times.”

“SPTS has been working closely with the leading MEMS manufacturers, foundries and research institutes for more than two decades, achieving an install base of over 1300 DRIE modules,” stated David Butler, General Manager of SPTS Technologies. “The Rapier DRIE process module provides the high-level of profile control, selectivity and uniformity needed for the critical feature requirements of next generation MEMS devices. We are pleased to bring this important capability to IMT’s foundry environment and be part of their exciting 200mm technology portfolio.”

IMT is already the largest pure-play MEMS foundry in the United States. With the Rapier, IMT is able to achieve best-in-class control over side-wall profile, scalloping, and aspect ratio, plus world-class etch rates, uniformity, and tilt control. By integrating SPTS’s patented Claritas end-point technology, IMT can implement precise control of the Si etch to a stop layer as commonly used for MEMS processing.

With the Rapier DRIE technology, IMT can better support its customers in the design, development, and manufacturing of devices that require superior deep silicon etching and maximum process control for optimum performance. IMT’s engineers will use industry-leading DRIE technology to improve throughput and yield in many types of devices including MEMS sensors and mirrors, photonics, microfluidic biochips, fiber blocks, lens arrays, silicon-optical benches and 3D interconnected devices using through-silicon vias (TSVs).