Picosun’s PicoArmour reduces semiconductor manufacturing costs

Picosun Group has pending patent rights for an ALD enabled corrosion protection solution against plasma etch that will bring benefits in semiconductor fabrication processes in terms of throughput, film uniformity and conformality. With PicoArmour the corrosion protection can be achieved more efficiently compared with the industry solutions commonly used today.

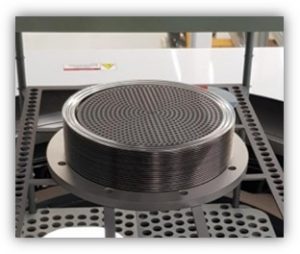

Wafer fabrication process flows include several steps where plasma etching is necessary. An inevitable consequence of using etching chemicals is that the tool itself will be etched. A common industrial solution for reducing the tool damage is applying a corrosion-resistant coating to the etch tool using for example PVD or spray coating with Y2O3. Compared to only using Y2O3, PicoArmour enables an up to five times faster and a more cost-effective way of producing the coating. Compared to Al2O3, the coating can be five times more durable.* Also, the maintenance interval of etch tools can be increased which also translates to significant reduction of manufacturing costs.

“Picosun’s approach with PicoArmour is to combine the highly-etch-resistant Y2O3 ALD process with more robust ALD processes. A high performance ALD corrosion barrier combining the speed and convenience of Al2O3 process with the durability of Y2O3 can be achieved by carefully controlling the film composition. With ALD, the protective effect can be achieved with thinner films, which in turn leads to material savings and a more environmentally friendly process”, states Juhana Kostamo, VP, Industrial Business Area of Picosun Group.