ACM Research announces China qualification

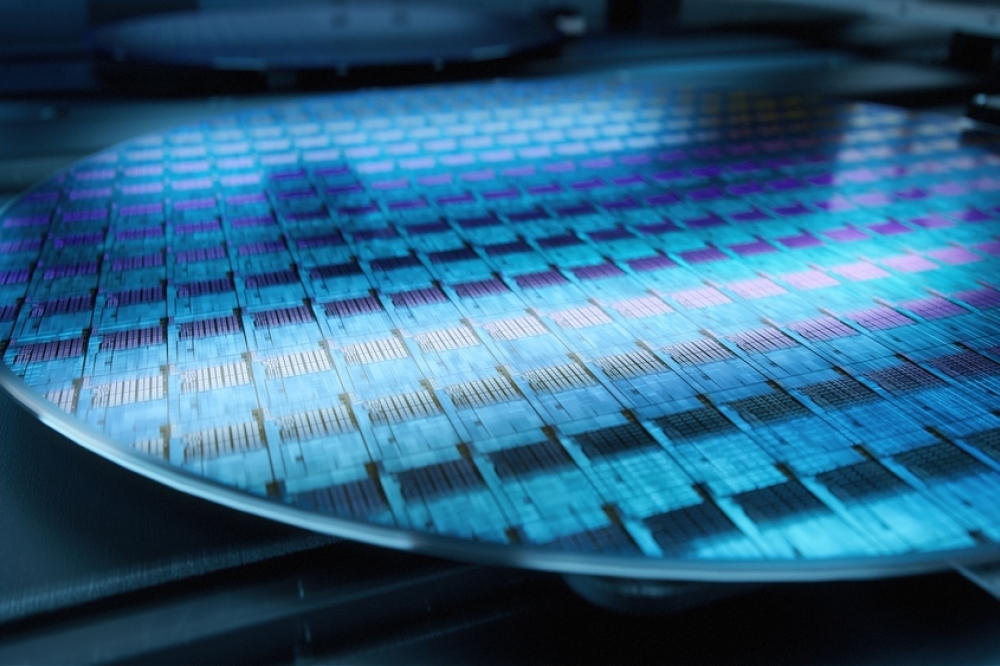

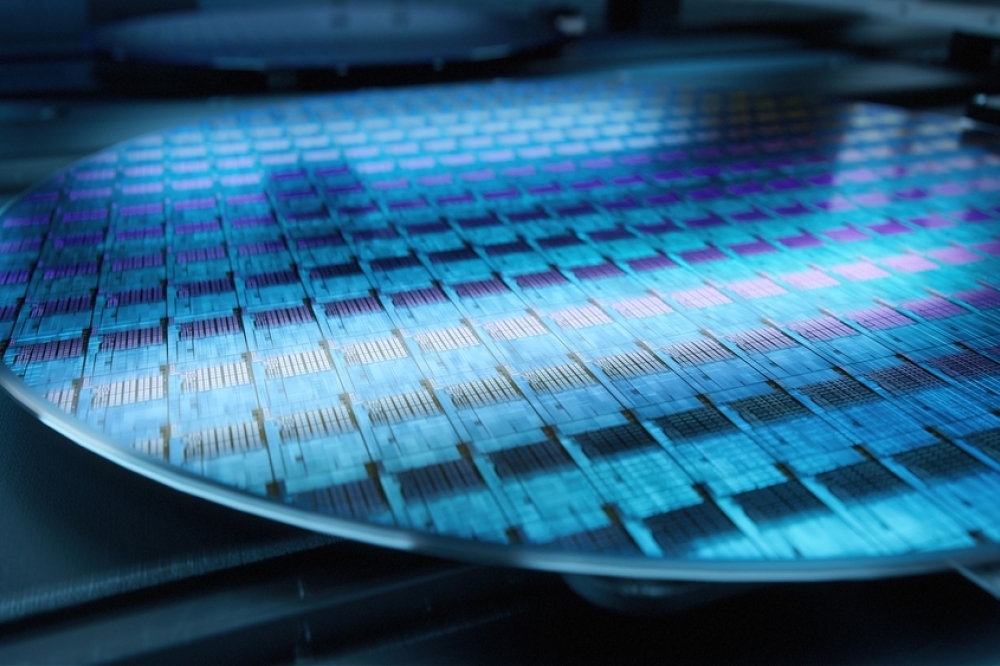

ACM Research says that its Single-Wafer High-Temperature Sulfuric Peroxide Mixture (SPM) tool has been qualified by a key logic device manufacturer in mainland China.

To date, ACM has delivered its SPM tools to 13 customers. The system features ACM’s proprietary nozzle design, which prevents acid mist splatter during the SPM process, improving particle performance, reducing chamber preventive maintenance cleaning frequency, and enhancing system uptime. It supports wet etching and wafer cleaning for both front- and back-end processes at 28-nanometer (nm) and below technology nodes.

“The Single-Wafer Moderate/High-Temperature SPM tool is a prime example of ACM’s commitment to innovation in solving customers’ challenges in high-volume 300mm semiconductor manufacturing. We’re already seeing great interest across our global customer base in this tool,” said Dr. David Wang, ACM’s President and Chief Executive Officer. “The Moderate/High-Temperature SPM represents a growing portion of the wafer-cleaning equipment market, especially High-Temperature SPM tool, which plays a critical role in manufacturing next-generation semiconductor devices.”

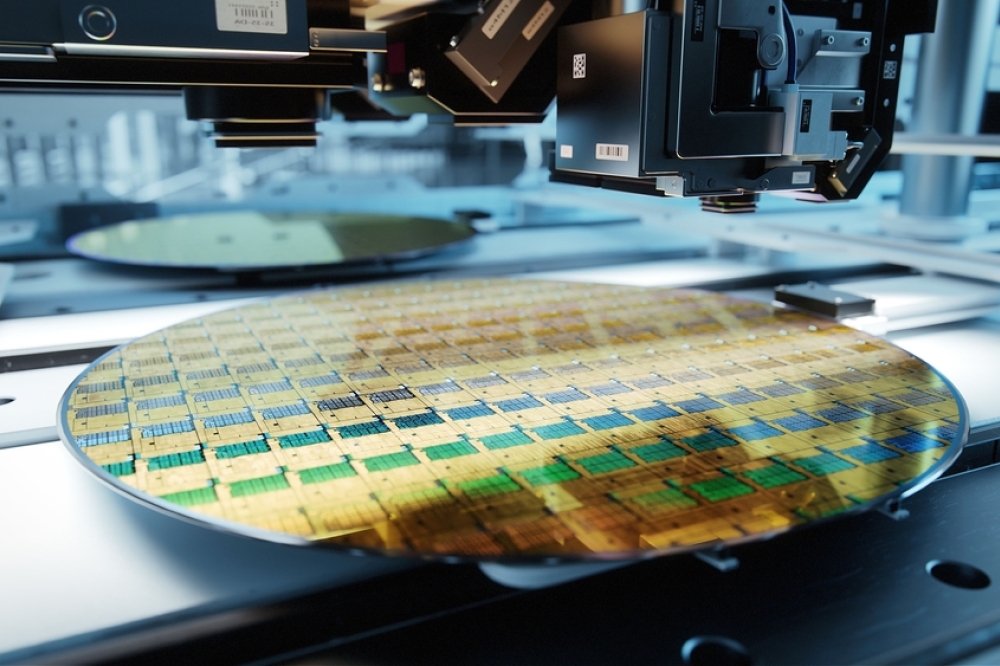

ACM’s Single-Wafer Moderate/High-Temperature SPM tool is suitable for a variety of front- and back-end wet etching and cleaning processes, including low-to-medium temperature sulfuric acid cleaning at 90 degrees Celsius (°C), high-temperature sulfuric acid photoresist stripping at 170°C, and ultra-high temperature sulfuric acid metal lift-off at 190°C. As semiconductor process nodes advance, the demand for single-wafer high-temperature sulfuric acid processing is increasing significantly. This trend brings increasingly stringent requirements for particle control, chamber environment management, and sulfuric acid temperature stability. In response to these challenges, ACM has introduced an innovative design for its Single-Wafer Moderate/High-Temperature SPM tool, positioning it as a ready-to-deploy solution to meet the evolving needs of the industry. ACM’s proprietary technologies integrated into the tool include:

A multi-level heating method that ensures the highest mixed temperature exceeds 230℃ and is steadily controlled.

An SPM nozzle design that prevents high-temperature SPM from splashing outside the chamber; it achieves better particle control with an average particle count of fewer than 10 at 26nm.

The Single-Wafer Moderate/High-Temperature SPM tool is equipped with an inline chemical mixing system and a configurable process chamber that accommodates various chemical solutions. It can also be seamlessly integrated with ACM's patented SAPS and TEBO megasonic technologies to enhance organic contaminant removal and improve wafer surface preparation.