MicroGen and Linear unite for MEMS energy harvesters

MicroGen's BOLT power Cells use Linear's LTC3588-1 piezoelectric energy harvesting conversion chip to power Dust Networks' motes

MicroGen Systems' vibration energy harvesting BOLT Power Cells enabled a live wireless sensor network (WSN) using Linear Technology's (Linear) Dust Networks LTC5800-IPM.

The SmartMesh IP mote-on-chip was demonstrated at the Sensors Expo and Conference exhibition in Rosemont, Illinois on June 5th and 6th, 2013.

The Linear mote was powered by MicroGen's piezoelectric Micro Electro Mechanical Systems (piezo-MEMS) vibrational energy harvester or micro-power generator (MPG) technology.

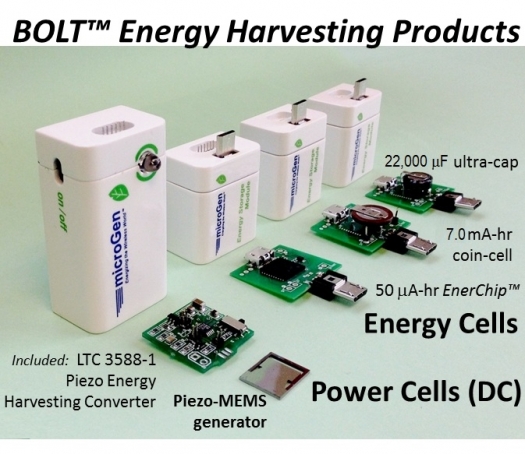

Shown in the image at the top of this story are MicroGen's piezo-MEMS based micro-power AC generator, Power Cells (9 Volt battery form-factor) with 3.3 Volt DC output, and plug-in Energy Cells that use either an ultra-capacitor or a rechargeable battery (solid-state or lithium ion coin batteries available) for additional energy storage capacity.

The Linear WSN consisted of four motes, and the company's WSN software for efficient power managed communication was used alongside. The self-powered motes were enabled by electronic shakers set at typical industrial vibrations levels of 120 Hz and acceleration G-level 0.2 g (g = 9.8 m/s²).

MicroGen placed vibration powered motes at the Linear booth and at the X-FAB MEMS Foundry booth. These motes were between 20 to 30 metres away from MicroGen's booth. The company says this was the first fully MEMS energy harvesting powered WSN completed by a commercial company.

Inside MicroGen's BOLT Power Cell is a small semiconductor MEMS chip fabricated using similar techniques as the computer chip industry. This chip, about 1 cm², is a piezo-MEMS MPG containing one end-mass loaded micro-cantilever containing a piezoelectric thin film.

As the MPG's cantilever bends up and down due to the external vibrational force it produces alternating current (AC) electricity. At resonance the AC power output is maximised, where it is ~ 100 microWatts at 120 Hz and ≥ 0.1 g, and ~ 900 microWatts at 600 Hz and ≥ 0.5 g.

The AC electricity is efficiently converted to direct current (DC) using Linear Technology's LTC3588-1 piezoelectric energy harvesting AC to DC converter. After the energy is scavenged it is temporarily stored on a 300 microFarad capacitor.

The output of the Power Cell ranges from 25-500 microWatts at 3.3 Volts DC, depending upon configuration and frequency. The BOLT Power Cell is intended to enable a wireless sensor mote from many different manufacturers.

The bottom-line is that the BOLT Power Cell is simply a battery replacement unit that uses vibrational energy instead of chemical energy produced by environmentally unfriendly materials.

The intent is to eliminate or extend the lifetime of primary cells or rechargeable batteries in WSN industrial and building applications, where the labour to frequently change batteries is cost prohibitive for a WSN to be installed. Power cells will be offered at 50/60 Hz harmonics between 100-1500 Hz.

MicroGen's MPGs and Power Cells are very sensitive to low levels of G. At G-levels less than 0.1 - 0.5 g, depending on frequency at a specific industrial signature frequency, then the Power Cell will enable the WS mote attached. In volume the MPG and Power Cell production cost are estimated be on the order of $0.50 and $1.00 each, respectively.

Joy Weiss, President of the Dust Networks product group at Linear Technology states, "I am pleased to see the progress that MicroGen is bringing to energy harvesting to enable self-powered SmartMesh wireless sensors."

Linear Technology's Boston Design Centre's Director, Sam Nork adds, "MicroGen's demonstration of its piezo-harvesting chip integrated with Linear Technology's LTC3588 piezo conversion chip is a perfect match to efficiently produce DC electricity for WSN applications."

MicroGen's CEO, Robert Andosca continues, "We are very pleased that we were able to show a low cost energy harvester solution to enable Linear Technology's SmartMesh wireless motes. Our goal is to provide piezo-MEMS harvesters in a form-factor that can be used by all wireless sensor products currently on the market. Our BOLT Power Cell is the first example of doing so with a commercial MEMS-based energy harvesting generator component."