Suppressing degradation in crystalline silicon solar cells

The developed technology puts a thin-film coating of STi's titanium oxide-based composite metal compound on the glass substrate used in PV modules.

Atsushi Masuda of the Collaborative Research Team and Kohjiro Hara of the Collaborative Module-Reliability Research Team, the Research Centre for Photovoltaic Technologies of the National Institute of Advanced Industrial Science and Technology (AIST), have developed a technology that suppresses output decline in crystalline silicon solar cells.

In particular they have researched the potential-induced degradation (PID), by coating the glass substrate with a thin film of titanium oxide-based composite metal compound, in collaboration with Sustainable Titania Technology Inc.

The technology involves putting a thin-film coating of titanium oxide-based composite metal compound on the glass substrate used in photovoltaic modules. This suppresses the diffusion of sodium ions, etc. from the glass substrate that is considered the major cause of PID.

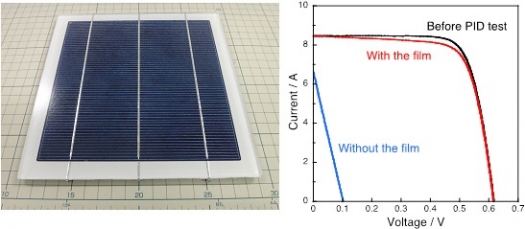

The figure at the top of this story shows the appearance of crystalline silicon photovoltaic module (18 cm à— 18 cm) treated for PID (left), and changes in current and voltage properties of photovoltaic modules as a result of treatment for PID (right).

The developed technology is expected to further enhance the reliability of crystalline silicon photovoltaic modules and help enhance the long-term reliability of mega solar and other solar power generation systems, installation of which is expected to accelerate in the near future.

Social Background of Research

With the start in Japan of the feed-in tariff system for electric power generated by renewable energy, the nation is experiencing a rapid expansion in the installation of solar power generation systems, including mega solar power plants.

At the same time, it has been reported from mega solar power plants outside Japan in recent years that the output of photovoltaic modules and systems declines greatly because of PID. This phenomenon differs from long-term degradation over the course of many years.

Rather than this, it reportedly can occur in a relatively short period of several months to a few years. Enhancing the long-term reliability of solar power generation systems and expanding their installation requires the elucidation of the mechanism of PID and the development of low-cost technology against it.

History of Research

Up to now, the Collaborative Module-Reliability Research Team, RCPVT, AIST has carried out research projects to increase the reliability and life of solar cell modules and further lower power generation costs.

These have included elucidating degradation mechanisms of existing photovoltaic modules, developing components and module structures to enhance module reliability, and developing new evaluation technology.

Among these efforts, the team has been working to elucidate the mechanism of PID, which is a problem in recent years because it greatly diminishes the reliability of photovoltaic modules and systems, and develop a technology against it.

For its part, STi has a business location in Saga Prefecture, one of the centres of ceramics technology, and has expertise in coating technologies with materials such as inorganic oxides.

For example, it has a technology to coat surfaces of glass, etc. with charge formation oxide thin films with a titanium oxide base for such uses as suppressing surface soiling and light reflection. Other manufacturers have adopted the technologies of STi.

AIST and STi have utilised the local industry and technologies of Saga Prefecture to enhance the reliability of solar cell modules and collaborated to develop technology against PID by coating the glass substrate of solar cell modules with an oxide-based compound thin film.

Details of Research

The developed technology puts a thin-film coating of STi's titanium oxide-based composite metal compound on the glass substrate used in photovoltaic modules. This prevents the diffusion of sodium ions, etc., which is considered the major cause of PID, from the glass substrate, suppressing the decline in output of solar cell modules.

Figure 1 outlines the construction of a standard crystalline silicon photovoltaic module and a PID-resistant module produced in this research. The thin film of titanium oxide-based composite metal compound is formed by coating the surface of the glass substrate (the crystalline silicon cell side) with a solution containing the starting material using the doctor blade method, drying it, and then annealing it . The glass substrate coated with the composite metal compound thin film, an EVA film (encapsulant), a crystalline silicon cell, and a back sheet are layered and vacuum-laminated to form a module.

Figure 1: Construction of standard module (left) and module treated for PID (right)

The properties of the standard module and treated module were each evaluated before and after PID testing. Figure 2 shows the current and voltage properties when illuminated by simulated sunlight before and after the PID testing (test conditions: -1000 V, 85 ℃, 2 hours).

The solar energy-to-electricity conversion efficiency of the standard module (without a thin-film coating) declined significantly, from 15.9 percent to 0.6 percent after the PID testing. In contrast, the treated module that uses the glass substrate coated with a thin film of titanium oxide-based composite metal compound underwent only a very slight decline in efficiency due to the PID testing.

It is believed that decline in output caused by PID was suppressed because the diffusion from the glass of sodium ions, etc., which is considered the major cause of PID, was blocked by the thin film of titanium oxide-based composite metal compound used in the experiment.

This technology has great potential for dealing with the PID phenomenon at low cost, for several reasons: the titanium oxide-based composite metal compound is relatively inexpensive, the film can be formed by a simple coating method and annealing at low temperature, and a small amount of material is used.

Figure 2: Current and voltage properties of standard module and treated module before and after PID testing

Future Plans

The researchers will seek to optimise the materials, film thickness, film-forming conditions, and so on for the thin film of titanium oxide-based composite metal compound in order to better suppress PID and verify the improved suppression. They also plan to elucidate the mechanism of PID suppression in more detail, conduct demonstrative tests with modules of larger surface area, and conduct other research and development, aiming at early commercialisation of the developed technology.