News Article

Presto, DelfMEMS to Design RF MEMS Test Solution

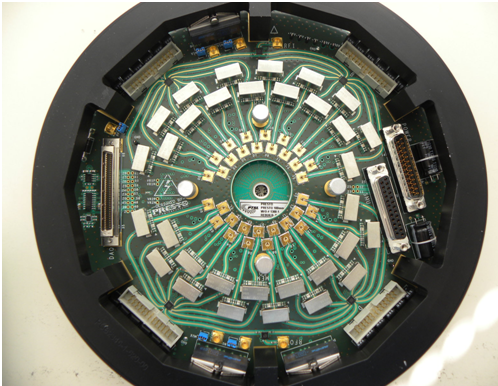

Presto Engineering Inc., a provider of semiconductor back-end turnkey production services, and DelfMEMS, a provider of MEMS devices for mobile applications, have announced that they have worked together to design, from specification to integration, the first full PXI-based test system for ultra-fast characterization testing of radio frequency (RF) micro-electro-mechanical-systems (MEMS). The PXI-based test cell significantly reduces total cost-of-ownership and speeds time-to-volume and yield optimization compared to currently prevailing test methods.

DelfMEMS, the first to market RF systems based on MEMS ohmic switches for mobile telephony applications, needed an innovative test solution.

According to Karim Segueni, CTO, DelfMEMS, "Presto Engineering exceeded our expectations in designing and developing this custom test system - meeting all of our specifications on time, and on budget. The new system has reduced wafer test time by a factor of ten compared to the manual bench test setup we were using. We will use it to validate the design of our new 4G LTE RF MEMS SPNT chip, and the faster cycle time will enable us to ramp to high-volume production more quickly and with better yield predictability."

Standard RF wafer probing approaches on automatic test equipment (ATE) are not cost-effective for device characterization during a ramp phase. Because of their high capital cost, ATE is best suited for high-volume production. Increasing throughput via parallel testing (several sites tested simultaneously) can reduce costs. This is especially true for the extremely low-cost, high-volume devices, such as RF MEMS for mobile phones. Characterization testing of these devices during the ramp phase, using either an ATE or bench test system, is, respectively, too expensive or too slow to meet the time-to-volume objective.

"Our innovative solution automates volume collection of data during the ramp phase with minimal cost-of-ownership. It is designed to facilitate easy re-use on devices regardless of their pin configurations, and is flexible enough to enable fast characterization for yield learning," stated Cédric Mayor, vice president technology & marketing, Presto Engineering. "Our biggest challenge in developing this system was achieving customer targets for <1 Ohm contact resistance and S-parameter on N-input/output for each device, keeping in mind a sufficient throughput capability."

The new test bench enables intensive device characterization during ramp-up phase by using an industrial solution capable of volume test production. It has been designed has a versatile measurement platform in order to fully characterize, both in the time-domain and frequency-domain, various RF-MEMS chips from the SPST till the SP16T configuration. It provides transient Kelvin measurement with a high-sampling rate (every 250ns) in order to characterize the dynamic operation (ON-state, OFF-state and switching events) and the lifetime of the RF MEMS relays from a mechanical and electrical standpoint. The same measurement hardware is also capable of performing RF measurement up to 6 GHz. The PXI-based solution easily handles the high volume of data typically collected in the characterization phase. In addition to characterizing RF-MEMS chips, the new test bench can serve as a platform to develop and validate test routines for volume-test production with ATE.