EVG and Dynaloy change cleaning packaging technology

Suited to 200 and 300mm wafers, the tool is claimed to use fewer chemicals, shorten process times and enable high wafer-to-wafer consistency

Scientists from Dynaloy, LLC and EV Group will explain a new, one-step cleaning process for removing negative dry film and negative spin-on film photoresist on April 24th, 2014 at the SEMATECH Surface Preparation and Cleaning Conference in Austin, Texas.

Authors from Dynaloy include Technology Manager Kim Pollard, Chemist Travis Acra, and Chemical Engineer Richard Peters.

Known as CoatsClean technology, this approach to cleaning represents an improvement in process technology. It uses fewer chemicals, shortens process times, enables high wafer-to-wafer consistency, and offers process flexibility. All of these advantages come together in this process that has its own tool, the newly developed EVG-300RS.

During the presentation, researchers will explain in detail how the CoatsClean technology process works.

CostClean process

First, coat the wafer with a small amount of a specially formulated cleaner, then heat the formulation on the wafer, and finish with a rinse. Local point-of-use heating offers flexibility by allowing different wafer types to be cleaned with the same tool in the same bowl, eliminating the cost and time involved in setting up transitions. This process works on several different wafer types for both 200mm and 300mm wafers.

"Unlike spray processes that require large quantities of liquid for cleaning, CoatsClean technology is less expensive because it involves comparatively small amounts of cleaning solution. This factor creates a lower cost of ownership and a decrease in cost per clean, two important considerations within the industry," says Pollard.

This new process also saves time by dramatically reducing the risks associated with bath immersions that use the same liquid for multiple batches. By using small quantities of fresh liquid for each clean, CoatsClean™ technology allows for a consistent process that protects the pre-clean integrity of the wafer.

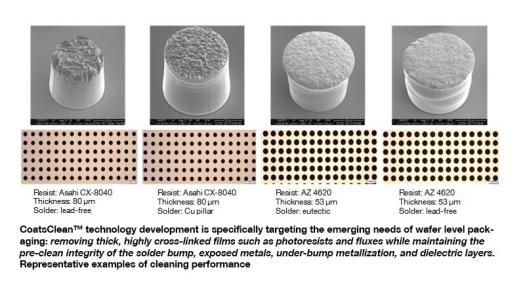

The presentation during SEMATECH will feature compelling visual evidence of how well CoatsClean technology removes photoresists and residue. During testing, researchers used a wet acid-based etch step to remove the copper field metal, a sensitive indicator for resist removal quality. They found no detectable irregularities in the optical microscopy images after copper field metal etching. Instead, they saw complete resist removal and a compatible copper surface finish.