SEMICON West: memsstar Launches Next-Generation MEMS Equipment

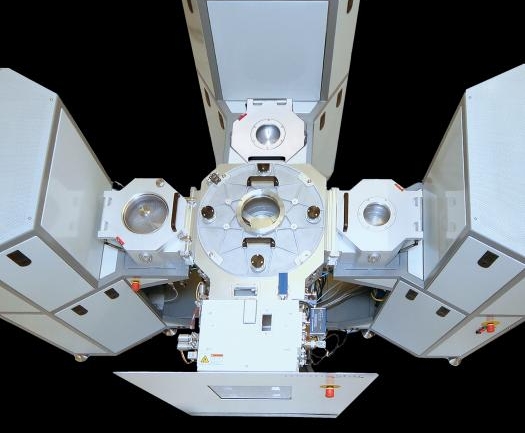

memsstar Limited, a provider of etch and deposition equipment and technology solutions to manufacturers of semiconductors and micro-electrical mechanical systems (MEMS), has launched its ORBISÂ platform of etch and deposition process tools for MEMS manufacturing. ORBIS systems deliver the industry's most advanced single-wafer process capability, required to meet the uniformity and repeatability requirements for advanced MEMS manufacturing.

"Adoption of MEMS technology is increasing rapidly, with the explosion of mobile devices, the 'Internet of Things' and the trillion sensors roadmap," said Tony McKie, CEO of memsstar. "With such diversity in applications and increasing performance and capability, manufacturers are clearly demanding process advances, as smaller, high-functionality MEMS devices can no longer tolerate process variations that impact performance. Our new ORBIS platforms build on our first-generation systems to deliver significant process and hardware enhancements that advance manufacturing capability and performance in the MEMS industry."

The ORBIS platform enhances memsstar's production-proven and unique processing technology, which has seen strong market acceptance and has become an enabling technology for next-generation MEMS manufacturing. On the process side, enhancements built into the ORBIS platform include fully integrated process monitoring and endpoint control, as well as a new high-selectivity package. At the same time, the platform's hardware has been upgraded, which results in even better uniformity and repeatability, critical to improving yield.

The new ORBIS platform consists of three models:

ORBIS ALPHAÂ targets institutions and universities involved in MEMS research and development (R&D) with a system based on memsstar's production-proven continuous-flow processing technology to enable next-generation process development on a cost-effective platform.

ORBIS 1000 is a single-wafer vacuum loadlock system designed for commercial R&D. It uses the same processing techniques as memsstar's volume production systems, and can be easily upgraded to a production system as business conditions change. Supported process modules include XERIXÂ oxide and silicon vapor phase etch and AURIXÂ SAM coatings.

ORBIS 3000 is a fully automated single-wafer platform that delivers the industry's most advanced MEMS manufacturing capability in the industry for high-volume production. It also supports the XERIX etch and AURIX coatings process modules.

"We have spent a considerable time working with customers to enhance our single-wafer architecture and technology to ensure that it will meet their manufacturing requirements now and in the future. The ORBIS platform incorporates all of these advances, increasing system performance and delivering the industry's most advanced release etch and surface modification equipment to our customers," concluded McKie.