Morgan announces PZT materials and advanced cutting, dicing and grinding capabilities

Morgan Advanced Materials (Morgan) has announced the availability of PZT (lead zirconate titanate) components, and assemblies at its Bedford, Ohio facility. Also offered are advanced PZT dicing, cutting, and grinding capabilities. The materials are ideal for use in consumer and high volume electronics, semiconductor, medical, SONAR and oil and gas markets.

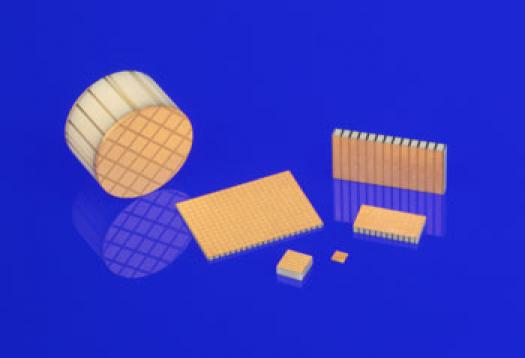

1-3 piezo composite componentsThe ISO 9001 and ISO 14001 compliant facility offers more than 30 compositions of PZT material in Navy Type I, II, III, V and VI variations. Morgan also manufactures unique materials in its standard material range with enhanced piezoelectric, permittivity, coupling, and aging rate properties. A dedicated team of technicians and transducer and composite engineers take projects from drawings to finished product, and from development to in-service and volume production.

In addition to its extensive material portfolio, the facility has strong PZT dicing and cutting capabilities, including the availability of dicing machines in clean rooms, ideal for customers requiring components for electronics, semi-conductor and medical markets. Morgan can dice sections with thicknesses of 0.006-0.360 inches and can cut up to 1-inch thick PZT. This allows the company to offer both very small and large plate dicing capabilities to tight tolerance and very clean finishes.

Dicing high precision, high and low frequency 1-3 and 2-2 composites ranging from 10 MHz to 100 kHz (0.0078-1-inch) is also performed, with a variety of choices of backfill materials to suit customers' specific applications.

Metallization of electrodes is another specialty, including use of sputtered materials like gold, nickel chromium, nickel vanadium, and aluminum. The facility processes fired-on silver (on standard PZT only), silver epoxy alternatives, and electroless nickel for electrical connections. Unique grinding capabilities mean Morgan can fine grind to thicknesses of 0.0030-inches for very thin plates and high frequency 1-3 composite designs, raising frequency capabilities up to 30MHz.