Advanced Surface Preparation for Soldermask and Photoresist Adhesion

CupraEtch SR is one of Atotech's surface pretreatment products, specifically developed to maximize the adhesion of dry and liquid soldermasks and photoresists. It is a sustainable and robust process, which satisfies ever increasing technology demands of PCB and HDI manufacturers and helps to minimize the risks of failure and damage during processing.

Primarily developed for treating copper surfaces prior to the Soldermask lamination, CupraEtch SR can also be used for Photoresist pretreatment for both I/L and O/L by simply employing a lower etch depth. The process provides excellent adhesion results and is ideal for the production of complex and demanding PCBs and HDIs, which need a reliable top performance.

CupraEtch SR - Applications

"The simple, low-temperature three-step-process is based on a cupric chloride etch. It is suitable for tenting as well as pattern plating applications and ideally suited for the conveyorized application of thin material handling," explains Dr. Rami Haidar, Global Product Manager Surface Treatment Technology (STT), at Atotech Deutschland GmbH in Berlin, Germany.

CupraEtch SR has shown its compatibility with multiple copper types and can be used with a wide variety of soldermasks as well as dry and liquid photoresists. It can also be used with various selective finishes such as IMT (immersion tin) and ENIG (electroless nickel, immersion gold).

CupraEtch SR - The benefits

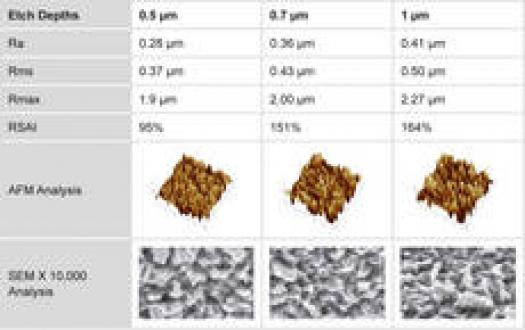

The superior adhesion performance leads to a lower defect rate and hence to better production yields. Additionally, the product has a high copper loading capacity of up to 40 g/L which results in reduced feed and bleed needs. This, in return, leads to lower waste water volumes and makes CupraEtch SR a sustainable and cost-saving process. The roughness creation can be finely balanced with etch depths, which makes this process adjustable to individual customer needs.

The cost-effective CupraEtch SR process is available in China, Taiwan, Korea, South East Asia and EU countries and is already successfully employed by several Atotech customers for both soldermask and photoresist pretreatment.