Nanoscale solution to big problem of overheating in microelectronic devices

Anyone who has ever toasted the top of their legs with their laptop or broiled their ear on a cell phone knows that microelectronic devices can give off a lot of heat. These devices contain a multitude of transistors, and although each one produces very little heat individually, their combined thermal output is significant and can damage the device.

Thermal management is an ongoing struggle for the electronics industry as there is currently no way to accurately measure temperature at the scale of individual microelectronic devices. Overheating is an even bigger problem for the roomfuls of servers needed in data storage.

Although their small size helps make transistors and other microelectronic devices useful, it foils attempts to determine which areas in the device are hottest. The mere introduction of a probe, typically larger than the microelectronic device itself, affects the device's temperature and precludes an accurate reading. As a result, microelectronic device manufacturers must rely on simulations alone to understand the temperatures inside individual devices.

"If you just simulated the temperature in a microelectronic device, the next thing you want to do is measure the temperature and see if you're right," said Matthew Mecklenburg, a senior staff scientist at the University of Southern California's Center for Electron Microscopy and Microanalysis (CEMMA). "But a persistent question has been how to make these measurements."

Associated with the USC Viterbi School of Engineering and the USC Dana and David Dornsife College of Letters, Arts and Sciences, USC CEMMA provides research tools for imaging, visualization, and analysis of nano-scale features and structures.

![]()

In a paper published in Science on February 6, a research team led by Mecklenburg and Chris Regan of University of California Los Angeles (UCLA), presented findings that are a major step forward in understanding temperatures in microelectronic devices.

To avoid altering the device's temperature they decided to forego a thermometric probe altogether. They realized that the material being imaged could act as its own thermometer.

All materials change volume depending on their temperature. Therefore, a material's temperature can be determined by carefully measuring its volume, or equivalently, its density. In this case, aluminum was used because its thermal expansion is relatively large.

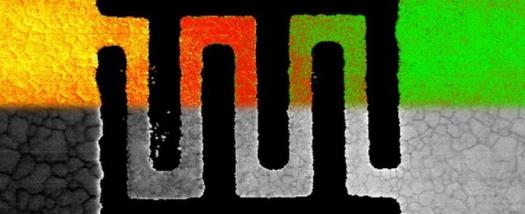

To measure its density the team aimed the imaging beam from a transmission electron microscope (TEM) at the aluminum, which caused the charges within the aluminum to oscillate. These charge oscillations, or plasmons, have long been known to shift depending on a material's density, but until now they had not been analyzed carefully enough to extract a local temperature measurement. Using the TEM and electron energy loss spectroscopy (EELS), the team was able to quantify the energy of the aluminum plasmon and precisely determine its temperature with nanometer-scale resolution.

"Every semiconductor manufacturer measures the size of their devices in transmission electron microscopes," said Mecklenburg. "Now, in the same microscope, they can measure temperature gradients in an individual device."

Named Plasmon Energy Expansion Thermometry (PEET), this new technique can be used to effectively measure the temperatures within a transistor by measuring the expansion of materials already contained in the device.

"This technique is sensitive to the bulk material, not just the surface," said Mecklenburg. "Measurements of temperatures hidden inside a device will enable better thermal management, which means faster transistors and lower power consumption: your cell phone will hold its charge longer."

The research team also included USC Viterbi associate professor Stephen Cronin and electrical engineering doctoral student Rohan Dhall, William Hubbard and E.R. White of UCLA as well as Shaul Aloni of the Lawrence Berkeley National Laboratory.

The team will next translate this technique to other materials including silicon, a staple in transistors. Many common metals and semiconductors have the proper characteristics that will allow them to serve as their own thermometers. By applying PEET to other materials used in CPUs and transistors, researchers will be able to accurately map temperatures in microelectronic devices while they are in operation, as well as develop more efficient CPUs and transistors that dissipate less heat.