Okmetic introduce enhanced SOI wafer

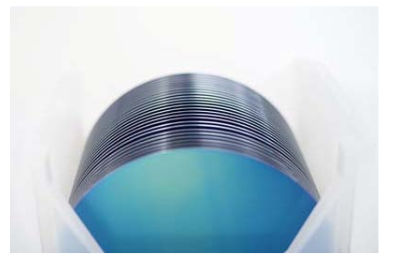

Okmetic has introduced an Enhanced SOI wafer (E-SOI) into its SOI product family (Silicon-On-Insulator).

The company believes that because of its new level of layer thickness uniformity and unprecedented properties E-SOI is an ideal platform for applications such as HV BCD devices, silicon photonics and high-precision silicon-based MEMS sensors.

"The device layer thickness of E-SOI is freely adjustable between 1.0 μm and >100 μm and the thickness tolerance independent of target thickness is as low as +/-0.1 μm. With the wide selection of silicon starting materials from Okmetic's in -house crystal growth, and similar flexibility in wafer customization as Okmetic BSOI wafers, the E-SOI technology provides an ideal wafer solution to both semiconductor and sensor applications", describes Senior Development Manager, Technology Jari Mäkinen, who was the leader of the development project.

Okmetic's SOI (Silicon-On-Insulator) wafers are manufactured by bonding technology. Two silicon wafers are bonded together, having an insulating oxide between. In a typical application sensing elements and possible IC devices are built on the active layer. Buried oxide is an effective etch-stop, and can also act as a sacrificial layer.

Handle wafer is supporting the structure but it can also be utilized in sealing the structure or as part of the sensing element. In addition to E-SOI, Okmetic's SOI family includes Bonded SOI (BSOI) and Cavity SOI (C-SOI) wafers.

"Okmetic's strategic focus is on high-performance wafers for the manufacture of sensors, discrete semiconductors and analog circuits. E-SOI complements Okmetic's wide product selection perfectly and provides our customers an ideal platform for the manufacture of high-end devices", concludes Anna-Riikka Vuorikari -Antikainen, Okmetic's Senior Vice President, Customers and Markets.